Expansion of the Automotive Sector

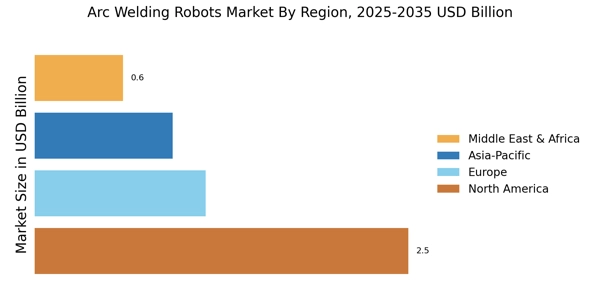

The Arc Welding Robots Market is closely linked to the expansion of the automotive sector, which continues to be a major driver of demand for robotic welding solutions. As automotive manufacturers seek to improve production efficiency and meet stringent quality standards, the adoption of arc welding equipment has become increasingly prevalent. Data suggests that the automotive industry accounts for a significant share of the overall market for welding robots, with projections indicating continued growth in vehicle production. This expansion is likely to propel the Arc Welding Robots Market forward, as manufacturers invest in automation to streamline their operations and enhance product quality.

Increased Focus on Safety and Ergonomics

The Arc Welding Robots Market is increasingly focused on safety and ergonomics, driven by the need to protect workers from hazardous environments. Welding operations can expose workers to harmful fumes, intense heat, and physical strain. By implementing robotic welding solutions, companies can significantly reduce the risk of workplace injuries and improve overall safety. Furthermore, the automation of welding tasks allows human workers to engage in more strategic roles, enhancing job satisfaction and productivity. As safety regulations become more stringent, the demand for arc welding robots is expected to rise, indicating a positive trajectory for the Arc Welding Robots Market.

Technological Advancements in Automation

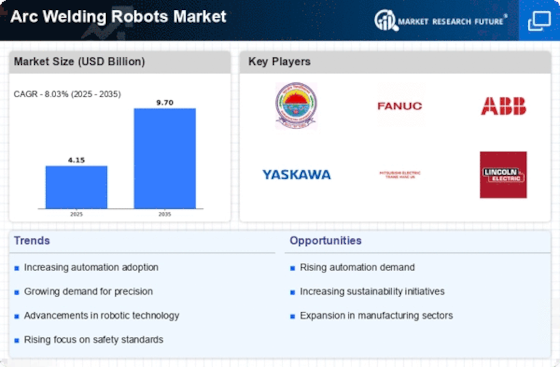

The Arc Welding Robots Market is experiencing a surge in technological advancements that enhance automation capabilities. Innovations in artificial intelligence and machine learning are enabling robots to perform complex welding tasks with greater precision and efficiency. For instance, the integration of vision systems allows robots to adapt to varying workpieces, thereby reducing setup times and increasing productivity. According to recent data, the market for robotic welding is projected to grow at a compound annual growth rate of approximately 7.5% over the next five years. This growth is driven by the need for higher quality welds and reduced labor costs, making automation an attractive option for manufacturers. As industries increasingly adopt these advanced technologies, the Arc Welding Robots Market is likely to expand significantly.

Rising Demand for Skilled Labor Alternatives

The Arc Welding Robots Market is witnessing a rising demand for alternatives to skilled labor, particularly in sectors facing labor shortages. As the workforce ages and fewer young workers enter skilled trades, companies are turning to automation to maintain production levels. The use of arc welding robots not only addresses labor shortages but also enhances consistency and quality in welding processes. Data indicates that the labor cost savings associated with robotic welding can be substantial, with some companies reporting reductions of up to 30% in labor expenses. This trend suggests that the Arc Welding Robots Market will continue to grow as businesses seek reliable solutions to mitigate the impacts of labor shortages.

Growing Investment in Manufacturing Technologies

The Arc Welding Robots Market is benefiting from growing investments in advanced manufacturing technologies. Industries are increasingly allocating resources to upgrade their production capabilities, with a focus on automation and robotics. This trend is particularly evident in sectors such as automotive and aerospace, where precision and efficiency are paramount. Recent statistics show that investments in manufacturing technologies are projected to reach unprecedented levels, with a significant portion directed towards robotic solutions. As companies strive to enhance their competitive edge, the Arc Welding Robots Market is likely to see substantial growth, driven by these investments.