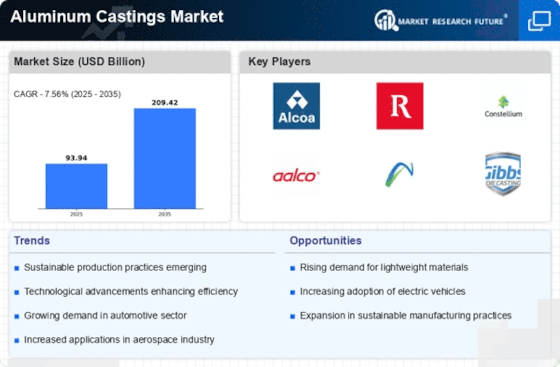

Rising Demand in Aerospace Sector

The Aluminum Castings Market is experiencing a notable surge in demand from the aerospace sector. This growth is primarily driven by the increasing need for lightweight materials that enhance fuel efficiency and performance. Aluminum castings are favored for their excellent strength-to-weight ratio, making them ideal for aircraft components. According to recent data, the aerospace industry is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years, further propelling the demand for aluminum castings. As manufacturers seek to optimize aircraft design and reduce operational costs, the Aluminum Castings Market is likely to benefit significantly from this trend.

Infrastructure Development Initiatives

Infrastructure development initiatives are significantly influencing the Aluminum Castings Market. Governments and private sectors are investing heavily in infrastructure projects, including bridges, buildings, and transportation systems. Aluminum castings are increasingly utilized in these applications due to their durability, corrosion resistance, and lightweight properties. Recent reports suggest that infrastructure spending is projected to grow by approximately 5% annually, creating a robust demand for aluminum castings in construction and civil engineering. This trend indicates a promising outlook for the Aluminum Castings Market as it aligns with global efforts to enhance infrastructure resilience and sustainability.

Growing Demand for Consumer Electronics

The Aluminum Castings Market is witnessing a growing demand driven by the consumer electronics sector. With the proliferation of electronic devices, manufacturers are increasingly utilizing aluminum castings for components such as housings and frames. Aluminum's lightweight and thermal conductivity properties make it an ideal choice for these applications. Recent market analyses indicate that the consumer electronics industry is expected to grow at a compound annual growth rate of around 6% in the next few years. This trend suggests a sustained demand for aluminum castings, as manufacturers seek to enhance product performance and aesthetics in the competitive electronics market.

Expansion in Electric Vehicle Production

The Aluminum Castings Market is poised for growth due to the rapid expansion of electric vehicle (EV) production. As automakers increasingly shift towards electric mobility, the demand for lightweight and efficient components has intensified. Aluminum castings are integral to the manufacturing of various EV parts, including battery housings and structural components. Recent statistics indicate that the electric vehicle market is expected to witness a compound annual growth rate of over 20% in the coming years. This transition not only enhances vehicle performance but also aligns with sustainability goals, thereby driving the Aluminum Castings Market forward.

Technological Innovations in Casting Processes

Technological innovations in casting processes are reshaping the Aluminum Castings Market. Advancements such as 3D printing and precision casting techniques are enhancing the efficiency and quality of aluminum castings. These innovations allow for more complex designs and reduced material waste, which are critical in meeting the evolving demands of various industries. The adoption of these technologies is expected to increase production rates and lower costs, thereby attracting more manufacturers to the Aluminum Castings Market. As these technologies continue to evolve, they may redefine manufacturing standards and practices within the industry.