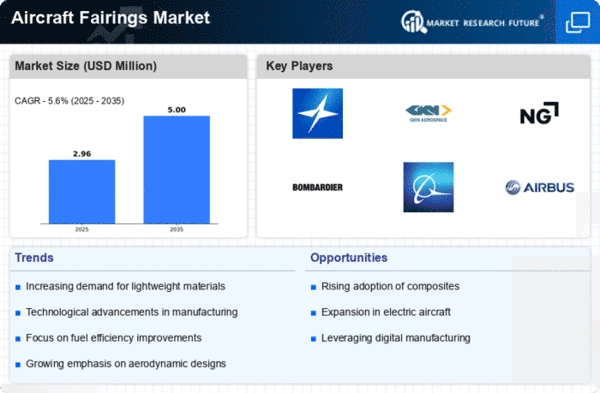

Market Growth Projections

The Global aircraft fairings Market Industry is projected to experience substantial growth in the coming years. With an estimated market value of 1.96 USD Billion in 2024, the industry is on a trajectory towards reaching 3.25 USD Billion by 2035. This growth is indicative of the increasing demand for aircraft fairings driven by advancements in technology, regulatory compliance, and the expansion of the aerospace sector. The anticipated CAGR of 4.7% from 2025 to 2035 further underscores the market's potential as it adapts to evolving industry needs and consumer preferences.

Expansion of the Aerospace Industry

The expansion of the aerospace industry is a pivotal driver for the Global Aircraft Fairings Market Industry. As global air travel continues to rise, driven by increasing passenger demand and cargo transport, the need for new aircraft and retrofitting existing ones becomes paramount. This growth in the aerospace sector directly correlates with the demand for aircraft fairings, as they play a crucial role in enhancing aerodynamic efficiency and reducing drag. The market is poised for growth, with estimates suggesting it could reach 3.25 USD Billion by 2035, reflecting the robust expansion of the aerospace industry and its impact on related components.

Focus on Environmental Sustainability

The Global Aircraft Fairings Market Industry is increasingly shaped by a focus on environmental sustainability. As the aviation sector faces pressure to reduce its carbon footprint, manufacturers are exploring eco-friendly materials and production methods. This shift towards sustainability not only addresses regulatory requirements but also aligns with consumer preferences for greener travel options. The development of fairings that utilize recyclable materials or have a lower environmental impact is becoming a priority. This trend is likely to drive innovation and investment in sustainable practices, contributing to the overall growth of the market as it adapts to the evolving landscape of environmental responsibility.

Regulatory Compliance and Safety Standards

The Global Aircraft Fairings Market Industry is significantly influenced by stringent regulatory compliance and safety standards imposed by aviation authorities. These regulations necessitate the use of high-quality materials and manufacturing practices to ensure the safety and reliability of aircraft components. As airlines and manufacturers strive to meet these standards, there is a growing demand for fairings that comply with international safety regulations. This focus on compliance not only enhances the safety of air travel but also drives innovation in fairing design and materials. Consequently, the market is expected to experience steady growth, with a projected CAGR of 4.7% from 2025 to 2035.

Increasing Demand for Lightweight Materials

The Global Aircraft Fairings Market Industry is witnessing a notable shift towards lightweight materials, driven by the aviation sector's emphasis on fuel efficiency and performance. Manufacturers are increasingly adopting advanced composites and polymers, which contribute to weight reduction without compromising structural integrity. This trend aligns with the industry's goal to enhance fuel economy, as lighter aircraft require less energy to operate. The integration of these materials is projected to support the market's growth, with the industry expected to reach 1.96 USD Billion in 2024, reflecting a growing preference for innovative solutions that optimize aircraft design and operational efficiency.

Technological Advancements in Manufacturing Processes

Technological innovations in manufacturing processes are significantly influencing the Global Aircraft Fairings Market Industry. The adoption of automated production techniques, such as 3D printing and advanced robotics, enhances precision and reduces lead times. These advancements allow manufacturers to produce complex fairing designs that were previously unattainable, thereby improving aerodynamic performance. As the industry evolves, the incorporation of smart manufacturing technologies is likely to streamline operations and reduce costs. This shift is anticipated to contribute to the market's expansion, with projections indicating a growth trajectory towards 3.25 USD Billion by 2035, highlighting the importance of technological integration in the sector.