Advancements in AI Technologies

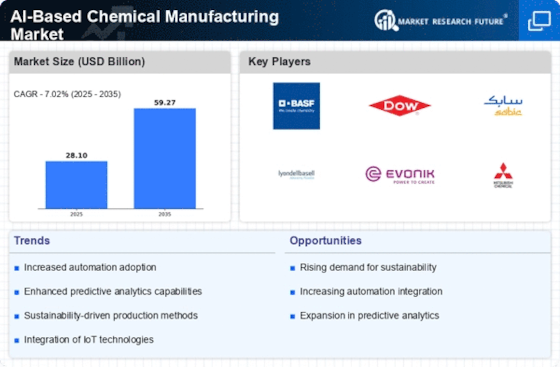

The rapid evolution of AI technologies is a significant driver in the AI-Based Chemical Manufacturing Market. Innovations in machine learning, data analytics, and predictive modeling are transforming how chemical manufacturers operate. These advancements enable companies to harness data more effectively, leading to improved product development and faster time-to-market. For example, AI algorithms can predict equipment failures, allowing for proactive maintenance and minimizing downtime. The market is expected to expand as manufacturers increasingly adopt these technologies, with projections indicating a compound annual growth rate of 15% over the next decade. This technological progression not only enhances operational capabilities but also fosters a culture of continuous improvement within the AI-Based Chemical Manufacturing Market.

Increased Demand for Efficiency

The AI-Based Chemical Manufacturing Market is witnessing a surge in demand for enhanced operational efficiency. Companies are increasingly adopting AI technologies to streamline production processes, reduce waste, and optimize resource allocation. According to recent data, AI-driven solutions can improve production efficiency by up to 30%, which is a compelling incentive for manufacturers. This drive towards efficiency not only lowers operational costs but also enhances product quality, making it a pivotal factor in the industry's growth. As manufacturers strive to meet rising consumer expectations and regulatory standards, the integration of AI technologies becomes essential. The potential for AI to analyze vast datasets in real-time allows for quicker decision-making and more agile responses to market changes, further solidifying its role in the AI-Based Chemical Manufacturing Market.

Enhanced Supply Chain Management

Effective supply chain management is crucial in the AI-Based Chemical Manufacturing Market. The integration of AI technologies allows for improved forecasting, inventory management, and logistics optimization. By leveraging AI, manufacturers can analyze market trends and consumer behavior to make informed decisions about production and distribution. This capability is particularly important in a market characterized by fluctuating demand and supply chain disruptions. Recent studies indicate that AI can reduce supply chain costs by up to 20%, which is a compelling reason for manufacturers to invest in these technologies. As the industry continues to evolve, the emphasis on robust supply chain management will likely drive further adoption of AI solutions, enhancing overall competitiveness in the AI-Based Chemical Manufacturing Market.

Regulatory Compliance and Safety

In the AI-Based Chemical Manufacturing Market, adherence to stringent regulatory standards is paramount. The increasing complexity of regulations surrounding chemical production necessitates the implementation of advanced technologies. AI can assist manufacturers in ensuring compliance by automating reporting processes and monitoring safety protocols. For instance, AI systems can analyze operational data to identify potential safety hazards before they escalate, thereby reducing the risk of accidents. Furthermore, the market is projected to grow as companies leverage AI to enhance their compliance strategies, with estimates suggesting a potential increase in market size by 20% over the next five years. This focus on safety and compliance not only protects workers but also enhances the reputation of manufacturers, making it a critical driver in the AI-Based Chemical Manufacturing Market.

Sustainability and Environmental Concerns

Sustainability is becoming a central theme in the AI-Based Chemical Manufacturing Market. As environmental regulations tighten and consumer preferences shift towards eco-friendly products, manufacturers are compelled to adopt sustainable practices. AI technologies facilitate this transition by optimizing resource use and minimizing waste. For instance, AI can analyze production processes to identify areas where energy consumption can be reduced, potentially lowering carbon footprints. The market is likely to see a significant increase in companies investing in AI solutions that promote sustainability, with estimates suggesting a 25% growth in this segment over the next five years. This alignment with sustainability not only meets regulatory demands but also enhances brand loyalty among environmentally conscious consumers, making it a vital driver in the AI-Based Chemical Manufacturing Market.