Increased Adoption in Various Industries

The 3D Optical Profiler Market is witnessing increased adoption across diverse sectors, including automotive, aerospace, and electronics. As industries strive for higher quality standards and precision in manufacturing processes, the demand for 3D optical profilers is on the rise. For instance, the automotive sector is utilizing these profilers for surface analysis to ensure optimal performance and safety of components. The electronics industry is also leveraging these tools for quality control in semiconductor fabrication. This broadening application spectrum is expected to contribute to a market growth rate of around 8% annually, reflecting the growing recognition of the importance of surface metrology. The increasing integration of 3D optical profilers into production lines signifies a transformative shift in how industries approach quality assurance, thereby solidifying their role in the 3D Optical Profiler Market.

Rising Investment in Research and Development

The 3D Optical Profiler Market is benefiting from rising investments in research and development across various sectors. Companies are increasingly allocating resources to innovate and improve optical profiling technologies, which is essential for maintaining competitive advantage. This investment trend is particularly evident in the semiconductor and materials science fields, where precision measurement is crucial. The market is projected to grow at a rate of around 7% as advancements in R&D lead to the development of next-generation optical profilers with enhanced capabilities. These innovations are likely to expand the application range of 3D optical profilers, making them indispensable tools in cutting-edge research and industrial applications. The focus on R&D not only drives technological progress but also solidifies the position of 3D optical profilers within the broader 3D Optical Profiler Market.

Focus on Sustainability and Eco-Friendly Practices

The 3D Optical Profiler Market is increasingly aligning with sustainability initiatives as companies prioritize eco-friendly practices. The shift towards sustainable manufacturing processes is prompting industries to adopt technologies that minimize waste and energy consumption. 3D optical profilers contribute to this goal by enabling precise measurements that reduce material waste during production. Furthermore, the ability to analyze surface textures and defects helps in optimizing resource usage, which is becoming a critical factor for compliance with environmental regulations. As sustainability becomes a core business strategy, the demand for 3D optical profilers is likely to rise, with projections indicating a potential market expansion of 10% in the coming years. This trend underscores the importance of integrating advanced measurement technologies into sustainable practices within the 3D Optical Profiler Market.

Growing Demand for Quality Control in Manufacturing

The 3D Optical Profiler Market is significantly driven by the growing demand for stringent quality control measures in manufacturing processes. As industries face increasing pressure to deliver high-quality products, the role of 3D optical profilers in ensuring surface integrity and precision becomes paramount. These profilers provide detailed surface topography data, which is essential for identifying defects and ensuring compliance with industry standards. The market is expected to witness a growth rate of approximately 9% as manufacturers recognize the value of integrating advanced metrology solutions into their quality assurance protocols. This trend highlights the critical role of 3D optical profilers in enhancing product reliability and performance, thereby reinforcing their importance in the 3D Optical Profiler Market.

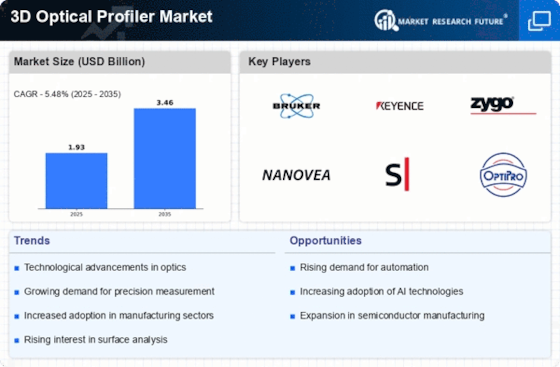

Technological Advancements in Measurement Techniques

The 3D Optical Profiler Market is experiencing a surge in technological advancements that enhance measurement precision and efficiency. Innovations such as high-resolution imaging and advanced algorithms are enabling more accurate surface characterization. These developments are crucial for industries like semiconductor manufacturing, where surface quality is paramount. The market is projected to grow at a compound annual growth rate of approximately 8% over the next five years, driven by the demand for high-performance optical profilers. As manufacturers continue to invest in R&D, the capabilities of 3D optical profilers are expected to expand, allowing for more complex applications in material science and nanotechnology. This trend indicates a robust future for the 3D Optical Profiler Market, as companies seek to leverage these advancements to improve product quality and operational efficiency.