How Tesla and BMW Slashed Downtime Using Predictive Maintenance in 2025

By 2025, Tesla and BMW have adopted predictive maintenance as a way to optimize operations within the automotive industry. Both companies have established AI maintenance systems to address equipment failures which has greatly improved unplanned downtime.

As a result of using AI to predict machinery health, Tesla was able to reduce factory downtime because of unexpected machine failures by over 30%. This predictive maintenance strategy aided Tesla’s California factory, further propelling them to the forefront of automotive manufacturing efficiency. Not only was productivity boosted, but the overall unit cost also decreased due to less spent on unmet deadlines.

As for BMW, the use of predictive AI maintenance heavily increased efficiency throughout the Regensburg plant. Predicative maintenance reduced the amount of Assembly line hold ups by over 500 minutes every year, allowing more units to be produced in less time. Not only did this aid in meeting production quotas, but the reduce met operational costs, allowing BMW to position themselves as leaders of industrial innovation.

The ramifications of predictive maintenance in 2025 goes past single manufacturers. The global market value for automotive predictive maintenance services is close to $2 billion in 2025, with an anticipated CAGR of 15% between the years 2025 and 2033. This advancement is fueled by the growing prevalence of connected vehicles and active enhancements.

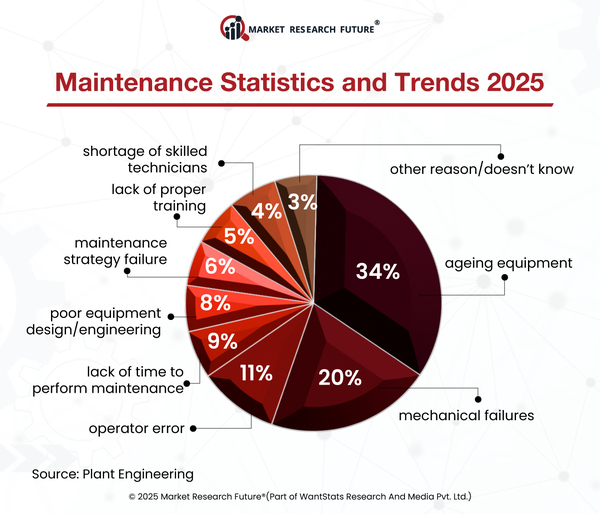

Moreover the value of predictive maintenance in 2025 is clear across multiple metrics: unplanned outages have been reduced by up to 30%, maintenance expenses shrank by 20% to 25%, and vehicle availability increased by 15% to 20%. Such changes lead to growing customer satisfaction, and a more agile automotive supply chain.

To summarize, the developments in AI powered predictive maintenance technologies by BMW and Tesla in 2025 showcases the impacts AIs have within manufacturing. With the ongoing changes within the automotive domain, it is certain that these systems will be universally adopted into mainstream vehicles, along with other innovation-driving features.