Sustainability Initiatives

Sustainability is becoming a pivotal focus within the Wire-cutting Machine Market, as manufacturers and consumers alike prioritize eco-friendly practices. The push for sustainable production methods is prompting companies to invest in energy-efficient wire-cutting machines that minimize environmental impact. For instance, machines that utilize less energy and produce less waste are gaining traction. Market data indicates that the demand for sustainable manufacturing solutions has increased by approximately 25% over the past year. This trend not only aligns with global environmental goals but also appeals to a growing segment of environmentally conscious consumers, thereby propelling the Wire-cutting Machine Market forward.

Increased Investment in Automation

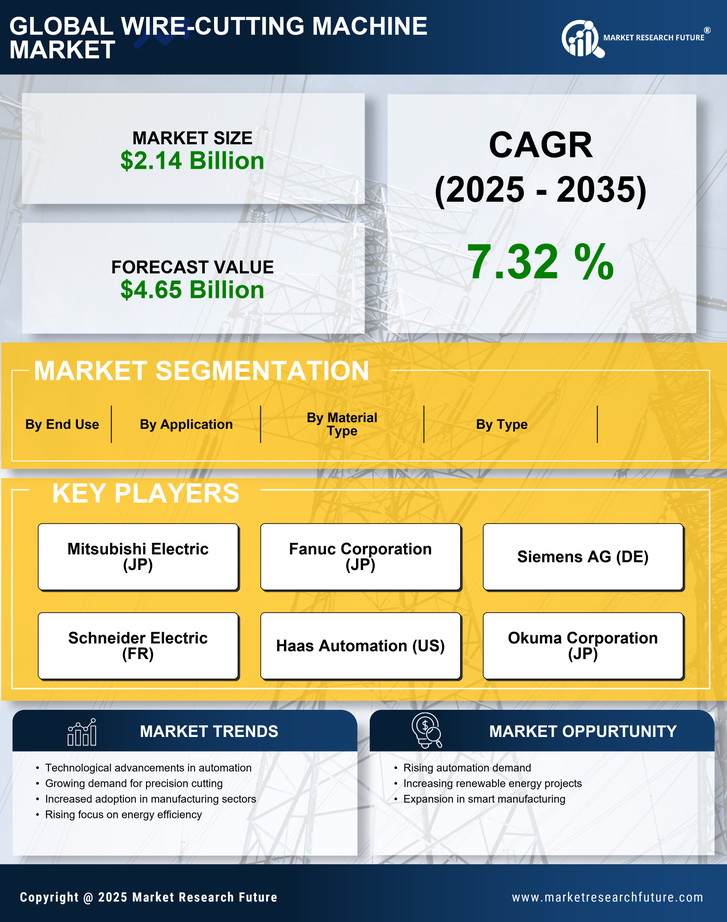

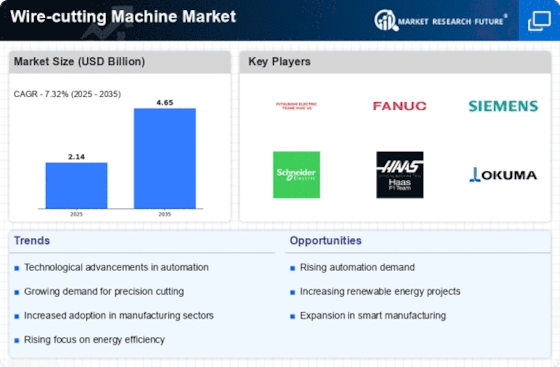

Increased investment in automation is reshaping the Wire-cutting Machine Market. As companies strive to enhance operational efficiency and reduce labor costs, the integration of automated wire-cutting machines is becoming more prevalent. Automation not only streamlines production processes but also improves accuracy and consistency in wire-cutting applications. Recent data indicates that the market for automated wire-cutting machines is projected to grow by 20% over the next five years. This trend suggests that as industries continue to embrace automation, the Wire-cutting Machine Market will likely experience substantial growth.

Rising Demand from Automotive Sector

The automotive sector is a significant driver of growth in the Wire-cutting Machine Market. As the automotive industry continues to evolve, the need for precise and efficient wire-cutting solutions is becoming increasingly critical. With the rise of electric vehicles and advanced automotive technologies, manufacturers require high-quality wire-cutting machines to meet stringent production standards. Recent statistics suggest that the automotive sector accounts for nearly 40% of the total demand for wire-cutting machines. This trend indicates a robust growth trajectory for the Wire-cutting Machine Market, as automotive manufacturers seek to enhance their production capabilities.

Expansion of Electronics Manufacturing

The expansion of the electronics manufacturing sector is significantly influencing the Wire-cutting Machine Market. As consumer electronics become more sophisticated, the demand for precise wire-cutting solutions is escalating. Manufacturers in the electronics sector require machines that can handle intricate designs and high volumes, which is driving innovation in wire-cutting technology. Current market analysis reveals that the electronics industry represents approximately 30% of the wire-cutting machine demand. This growth is expected to continue as new technologies emerge, further propelling the Wire-cutting Machine Market.

Technological Advancements in Wire-cutting Machines

The Wire-cutting Machine Market is experiencing a surge in technological advancements, which are enhancing the efficiency and precision of wire-cutting processes. Innovations such as automation, computer numerical control (CNC), and advanced software integration are becoming increasingly prevalent. These technologies not only improve the speed of operations but also reduce material waste, thereby optimizing production costs. According to recent data, the adoption of CNC technology in wire-cutting machines has led to a 30% increase in productivity for manufacturers. As industries seek to streamline operations and improve product quality, the demand for technologically advanced wire-cutting machines is likely to rise, driving growth in the Wire-cutting Machine Market.