Predictive Maintenance for Manufacturing Market Summary

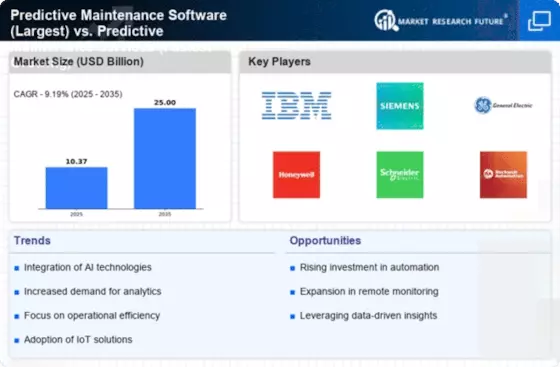

As per MRFR analysis, the Predictive Maintenance for Manufacturing Market Size was estimated at 9.5 USD Billion in 2024. The Predictive Maintenance for Manufacturing industry is projected to grow from 10.37 USD Billion in 2025 to 25.0 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 9.19 during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Predictive Maintenance for Manufacturing Market is poised for substantial growth driven by technological advancements and increasing operational demands.

- The integration of IoT technologies is transforming predictive maintenance practices across various manufacturing sectors.

- Data analytics advancements are enhancing the accuracy and efficiency of predictive maintenance solutions, particularly in North America.

- The focus on sustainability is becoming a pivotal factor in shaping maintenance strategies, especially within the automotive industry.

- Rising demand for operational efficiency and advancements in machine learning and AI are key drivers propelling the growth of predictive maintenance services in the Asia-Pacific region.

Market Size & Forecast

| 2024 Market Size | 9.5 (USD Billion) |

| 2035 Market Size | 25.0 (USD Billion) |

| CAGR (2025 - 2035) | 9.19% |

Major Players

IBM (US), Siemens (DE), GE (US), Honeywell (US), Schneider Electric (FR), Rockwell Automation (US), SAP (DE), PTC (US), Microsoft (US)