Technological Innovations

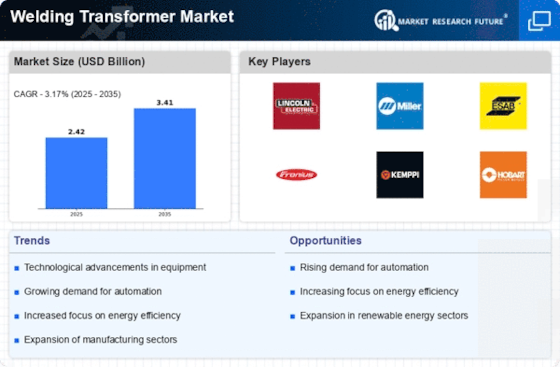

Technological advancements play a crucial role in shaping the Welding Transformer Market. Innovations such as inverter technology and digital control systems enhance the efficiency and performance of welding transformers. These advancements not only improve energy consumption but also provide greater precision in welding applications. In 2025, the market is expected to witness a shift towards more sophisticated welding equipment, with inverter-based transformers gaining popularity due to their lightweight and portable nature. This shift is indicative of a broader trend towards automation and smart technologies in the welding sector. As manufacturers continue to invest in research and development, the Welding Transformer Market is poised for significant growth, driven by the introduction of cutting-edge products that cater to diverse industrial needs.

Increased Focus on Renewable Energy

The Welding Transformer Market is likely to benefit from the growing emphasis on renewable energy projects. As nations strive to transition towards sustainable energy sources, the demand for welding transformers in the renewable sector is expected to rise. Applications in solar panel manufacturing and wind turbine assembly require high-quality welding solutions, which are facilitated by advanced transformers. In 2025, investments in renewable energy infrastructure are projected to reach unprecedented levels, creating a favorable environment for the Welding Transformer Market. This trend not only supports the growth of the market but also aligns with global sustainability goals, as industries seek to reduce their carbon footprint through efficient welding processes.

Rising Demand in Construction Sector

The Welding Transformer Market experiences a notable surge in demand driven by the expanding construction sector. As infrastructure projects proliferate, the need for robust welding solutions becomes paramount. In 2025, the construction industry is projected to grow at a compound annual growth rate of approximately 5.5%, thereby increasing the requirement for welding transformers. These devices are essential for various applications, including steel fabrication and metal joining, which are integral to construction activities. The Welding Transformer Market is likely to benefit from this trend, as manufacturers strive to meet the escalating demand for efficient and reliable welding equipment. Furthermore, the emphasis on quality and safety in construction practices necessitates the use of advanced welding technologies, further propelling the market forward.

Expansion of Automotive Manufacturing

The automotive industry serves as a significant driver for the Welding Transformer Market. With the continuous evolution of vehicle manufacturing techniques, the demand for high-performance welding equipment is on the rise. In 2025, the automotive sector is anticipated to grow, particularly with the increasing production of electric vehicles, which require specialized welding processes. The need for lightweight materials and advanced joining techniques in automotive manufacturing further propels the demand for welding transformers. As manufacturers adapt to these changes, the Welding Transformer Market is expected to witness substantial growth, driven by the necessity for innovative welding solutions that meet the stringent requirements of modern automotive production.

Growing Industrialization in Emerging Economies

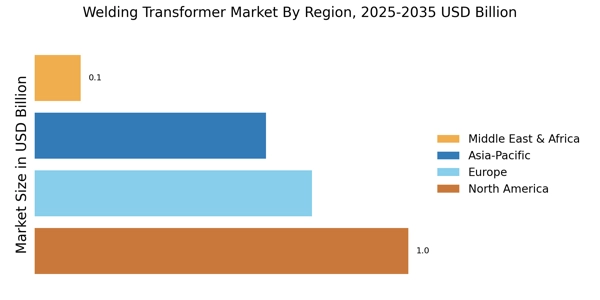

Emerging economies are witnessing rapid industrialization, which significantly impacts the Welding Transformer Market. As these nations develop their manufacturing capabilities, the demand for welding transformers is expected to rise. In 2025, countries in Asia and Africa are projected to experience substantial growth in their industrial sectors, leading to increased investments in welding technologies. This trend is indicative of a broader shift towards modernization and efficiency in manufacturing processes. The Welding Transformer Market stands to gain from this industrial expansion, as businesses seek reliable and efficient welding solutions to enhance productivity. Furthermore, the growing workforce in these regions necessitates training and development in welding techniques, further driving the demand for advanced welding transformers.