Emergence of 5G Technology

The rollout of 5G technology is poised to be a transformative force for the wafer fabrication market. As 5G networks become more prevalent, the demand for advanced semiconductors that can support higher data rates and lower latency is expected to surge. Analysts predict that the 5G infrastructure market could reach $1 trillion by 2030, creating a substantial opportunity for the wafer fabrication market. This shift necessitates the development of new materials and fabrication techniques to produce chips that can handle the increased performance requirements associated with 5G applications.

Growth of Automotive Electronics

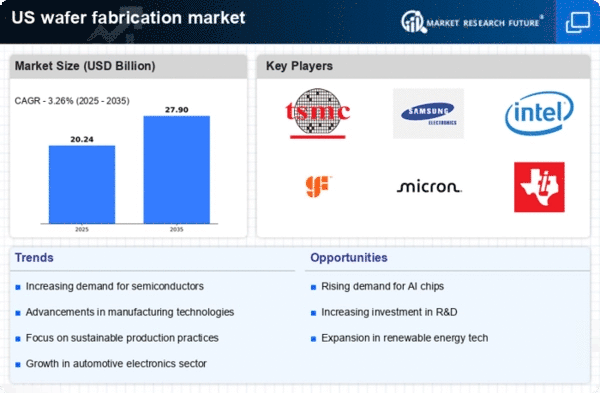

The automotive sector's transition towards electric and autonomous vehicles is driving significant changes in the wafer fabrication market. As vehicles become more reliant on advanced electronics, the demand for high-quality semiconductors is expected to rise. In 2025, the automotive electronics market is projected to grow by 7%, which will likely lead to increased investments in wafer fabrication technologies. The wafer fabrication market must respond to this trend by enhancing production capabilities and developing specialized chips that cater to the unique needs of automotive applications, such as safety and efficiency.

Government Support and Investment

Government initiatives aimed at bolstering domestic semiconductor manufacturing significantly impact the wafer fabrication market. In recent years, the US government has allocated substantial funding to support semiconductor research and development, with investments exceeding $50 billion. This financial backing is intended to enhance the competitiveness of the wafer fabrication market, ensuring that it can meet both current and future demands. Such support not only fosters innovation but also encourages collaboration between public and private sectors, ultimately leading to advancements in fabrication technologies and increased production capacity.

Rising Demand for Consumer Electronics

The increasing demand for consumer electronics is a primary driver of the wafer fabrication market. As technology continues to advance, consumers are seeking more sophisticated devices, which in turn drives the need for high-performance semiconductors. In 2025, the consumer electronics sector is projected to grow by approximately 5.5%, leading to a corresponding increase in semiconductor production. This growth necessitates enhanced wafer fabrication processes to meet the rising requirements for miniaturization and efficiency. The wafer fabrication market must adapt to these trends by investing in innovative technologies and optimizing production capabilities to satisfy consumer expectations.

Increased Focus on Research and Development

The wafer fabrication market is experiencing a heightened emphasis on research and development (R&D) as companies strive to innovate and maintain competitive advantages. With R&D expenditures in the semiconductor sector reaching approximately $40 billion in 2025, firms are investing heavily in new fabrication techniques and materials. This focus on R&D is crucial for addressing the challenges posed by evolving technology demands and ensuring that the wafer fabrication market can produce cutting-edge products. As a result, companies that prioritize R&D are likely to gain a significant edge in the increasingly competitive landscape.