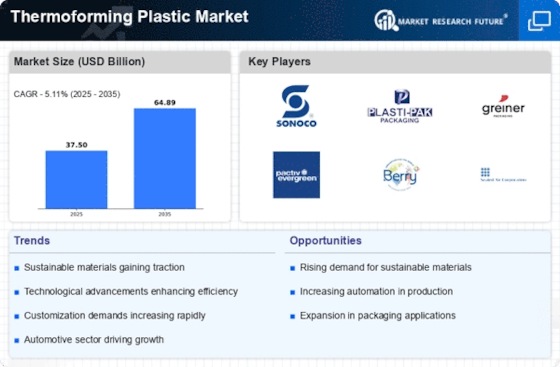

Growth in Automotive Applications

The automotive sector is a significant driver for the Thermoforming Plastic Market, as manufacturers increasingly adopt thermoformed plastics for various components. These materials offer advantages such as weight reduction, which contributes to improved fuel efficiency and lower emissions. In 2025, the automotive segment is expected to represent a considerable portion of the market, with applications ranging from interior components to exterior panels. The trend towards electric vehicles further enhances the relevance of thermoformed plastics, as lightweight materials are essential for optimizing battery performance. Furthermore, the ability to customize thermoformed products allows automotive manufacturers to meet specific design and functionality requirements. Consequently, the Thermoforming Plastic Market is poised for growth, driven by the automotive sector's evolving demands.

Increased Focus on Sustainability

Sustainability is becoming a central theme within the Thermoforming Plastic Market, as consumers and businesses alike prioritize eco-friendly solutions. The demand for recyclable and biodegradable materials is on the rise, prompting manufacturers to innovate and develop sustainable thermoformed products. In 2025, the market is expected to see a significant shift towards materials that minimize environmental impact, aligning with global sustainability goals. This trend is further supported by regulatory pressures and consumer awareness regarding plastic waste. Companies that embrace sustainable practices are likely to gain a competitive edge, as they appeal to environmentally conscious consumers. Consequently, the Thermoforming Plastic Market is set to evolve, reflecting the growing emphasis on sustainability in product development.

Rising Demand in Packaging Sector

The Thermoforming Plastic Market is experiencing a notable surge in demand, particularly within the packaging sector. This growth is driven by the increasing need for lightweight, durable, and cost-effective packaging solutions. In 2025, the packaging segment is projected to account for a substantial share of the market, as companies seek to enhance product protection while minimizing material usage. The shift towards e-commerce and online retailing further amplifies this demand, as efficient packaging becomes essential for shipping and handling. Additionally, the emphasis on sustainable packaging solutions is prompting manufacturers to explore innovative thermoformed products that align with environmental goals. As a result, the Thermoforming Plastic Market is likely to witness a robust expansion, catering to the evolving needs of the packaging landscape.

Expansion in Consumer Goods Sector

The consumer goods sector is emerging as a vital driver for the Thermoforming Plastic Market, with an increasing array of applications in household products, electronics, and personal care items. The versatility of thermoformed plastics allows for innovative designs and functional packaging that enhance user experience. In 2025, this sector is projected to contribute significantly to market growth, as manufacturers leverage thermoforming technology to create aesthetically pleasing and practical products. The rise of disposable and single-use items, coupled with the demand for convenience, further fuels this expansion. As consumer preferences evolve, the Thermoforming Plastic Market is likely to adapt, offering tailored solutions that meet the dynamic needs of the consumer goods landscape.

Technological Innovations in Manufacturing

Technological advancements are playing a pivotal role in shaping the Thermoforming Plastic Market. Innovations in manufacturing processes, such as improved heating techniques and automated production lines, are enhancing efficiency and product quality. In 2025, the market is likely to benefit from these advancements, as manufacturers seek to reduce production costs while maintaining high standards. The integration of smart technologies, including IoT and AI, is also expected to streamline operations and optimize resource management. These innovations not only improve the overall performance of thermoformed products but also enable customization options that cater to diverse consumer preferences. As a result, the Thermoforming Plastic Market is anticipated to thrive, driven by the continuous evolution of manufacturing technologies.