Growth in the Food and Beverage Sector

The Thermoformed Plastic Product Market is significantly influenced by the expansion of the food and beverage sector. With the increasing demand for convenient and ready-to-eat food options, thermoformed packaging solutions are becoming essential. These products offer excellent barrier properties, ensuring food safety and extending shelf life. Recent statistics indicate that the food packaging market is expected to reach a valuation of over 400 billion dollars by 2026, with thermoformed plastics capturing a substantial share. The lightweight nature of these materials also contributes to reduced transportation costs, making them an attractive option for food manufacturers. As the trend towards convenience continues, the demand for thermoformed plastic products in food packaging is likely to rise, further driving growth in the industry.

Rising Demand for Eco-Friendly Packaging

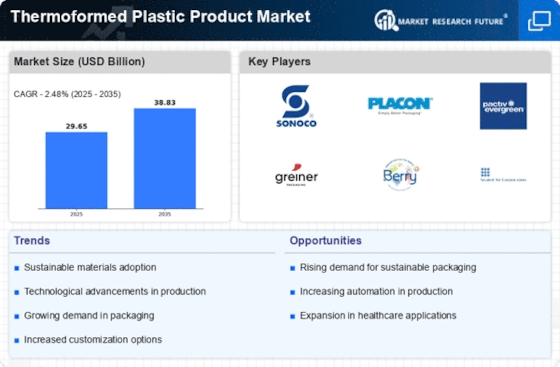

The Thermoformed Plastic Product Market is experiencing a notable shift towards eco-friendly packaging solutions. As consumers become increasingly aware of environmental issues, there is a growing preference for sustainable materials. This trend is reflected in the rising demand for thermoformed products made from recyclable and biodegradable plastics. According to recent data, the market for sustainable packaging is projected to grow at a compound annual growth rate of approximately 7.5% over the next five years. Companies are investing in innovative materials and processes to meet this demand, which is likely to drive growth in the thermoformed plastic sector. Furthermore, regulatory pressures aimed at reducing plastic waste are prompting manufacturers to adopt more sustainable practices, thereby enhancing the appeal of thermoformed plastic products in various industries.

Customization Trends in Consumer Products

Customization is emerging as a pivotal driver in the Thermoformed Plastic Product Market. As consumers increasingly seek personalized products, manufacturers are adapting their offerings to meet these preferences. Thermoforming allows for the creation of tailored designs that cater to specific consumer needs, whether in packaging or product design. This trend is particularly evident in sectors such as cosmetics and electronics, where unique packaging can enhance brand identity and consumer experience. Market analysis suggests that the customization segment is expected to grow at a rate of approximately 6% annually, reflecting the rising consumer demand for individualized products. As companies invest in flexible manufacturing processes, the ability to produce small batches of customized thermoformed products will likely become a competitive advantage, further propelling the industry's growth.

Advancements in Manufacturing Technologies

Technological innovations are playing a crucial role in shaping the Thermoformed Plastic Product Market. The introduction of advanced manufacturing techniques, such as automation and 3D printing, is enhancing production efficiency and product quality. These technologies enable manufacturers to produce complex designs with greater precision and at lower costs. For instance, the implementation of computer-aided design (CAD) systems allows for rapid prototyping and customization, which is increasingly demanded by consumers. The market is witnessing a shift towards smart manufacturing, where data analytics and IoT are utilized to optimize production processes. This trend is expected to contribute to a projected increase in market size, with estimates suggesting a growth rate of around 5% annually over the next few years. As manufacturers embrace these advancements, the thermoformed plastic products are likely to become more versatile and appealing to a broader range of applications.

Increased Investment in Research and Development

Investment in research and development is a critical driver for the Thermoformed Plastic Product Market. Companies are increasingly allocating resources to innovate and improve product offerings, focusing on enhancing performance and sustainability. This trend is evident in the development of new materials that offer better durability and environmental benefits. Recent reports indicate that R&D spending in the plastics sector is projected to increase by 10% over the next few years, as firms strive to stay competitive. Innovations such as bio-based plastics and advanced recycling technologies are gaining traction, which could reshape the market landscape. As manufacturers prioritize R&D, the thermoformed plastic products are likely to evolve, meeting the changing demands of consumers and regulatory standards, thereby fostering industry growth.