Increased Regulatory Compliance

The Teflon Heat Exchanger Market is also being driven by heightened regulatory compliance across various sectors. Industries are increasingly required to adhere to stringent environmental and safety regulations, which necessitate the use of materials that can withstand harsh conditions without compromising performance. Teflon heat exchangers, known for their durability and resistance to chemical degradation, are becoming a preferred choice for companies aiming to meet these regulatory standards. As regulations continue to evolve, the demand for Teflon heat exchangers is expected to rise, as they provide a reliable solution for industries such as pharmaceuticals and food processing, where compliance is critical. This trend indicates a growing recognition of the importance of using high-quality materials in heat exchange applications.

Growing Focus on Energy Efficiency

The Teflon Heat Exchanger Market is witnessing a growing focus on energy efficiency, driven by both economic and environmental considerations. As industries strive to reduce energy consumption and lower operational costs, the demand for efficient heat exchangers is on the rise. Teflon heat exchangers offer superior thermal performance, which can lead to significant energy savings in various applications. Recent studies suggest that implementing energy-efficient heat exchange systems can reduce energy costs by up to 30%. This potential for cost savings is likely to encourage more industries to adopt Teflon heat exchangers as part of their energy management strategies. Consequently, the Teflon Heat Exchanger Market is expected to experience robust growth as organizations prioritize energy efficiency in their operations.

Expansion in Renewable Energy Sector

The Teflon Heat Exchanger Market is poised to benefit from the ongoing expansion in the renewable energy sector. As the world shifts towards sustainable energy sources, the need for efficient thermal management systems becomes increasingly critical. Teflon heat exchangers are particularly well-suited for applications in solar thermal systems and geothermal energy, where high temperatures and corrosive fluids are prevalent. The renewable energy sector is anticipated to grow significantly, with investments projected to reach trillions of dollars in the coming years. This growth is likely to create new opportunities for Teflon heat exchangers, as industries seek reliable solutions to optimize energy conversion processes. Consequently, the Teflon Heat Exchanger Market may see a marked increase in demand as renewable energy technologies continue to evolve.

Rising Demand in Chemical Processing

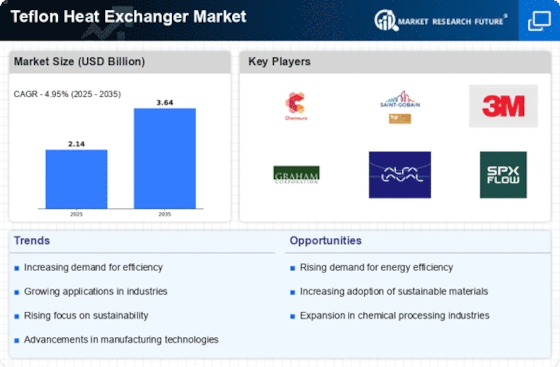

The Teflon Heat Exchanger Market is experiencing a notable increase in demand, particularly within the chemical processing sector. This surge is attributed to the need for efficient heat transfer solutions that can withstand corrosive environments. Teflon's unique properties, such as its chemical resistance and thermal stability, make it an ideal choice for heat exchangers used in various chemical applications. According to recent data, the chemical processing industry is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years, further driving the demand for Teflon heat exchangers. As industries seek to enhance operational efficiency and reduce maintenance costs, the adoption of Teflon heat exchangers is likely to expand, positioning the Teflon Heat Exchanger Market for substantial growth.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are significantly influencing the Teflon Heat Exchanger Market. Innovations such as improved fabrication techniques and enhanced material formulations are enabling the production of more efficient and durable heat exchangers. These advancements not only enhance the performance of Teflon heat exchangers but also reduce production costs, making them more accessible to a wider range of industries. For instance, the introduction of advanced welding techniques has improved the integrity and reliability of heat exchangers, which is crucial for industries that require high-performance equipment. As manufacturers continue to invest in research and development, the Teflon Heat Exchanger Market is likely to witness a surge in innovative products that meet the evolving needs of various sectors.