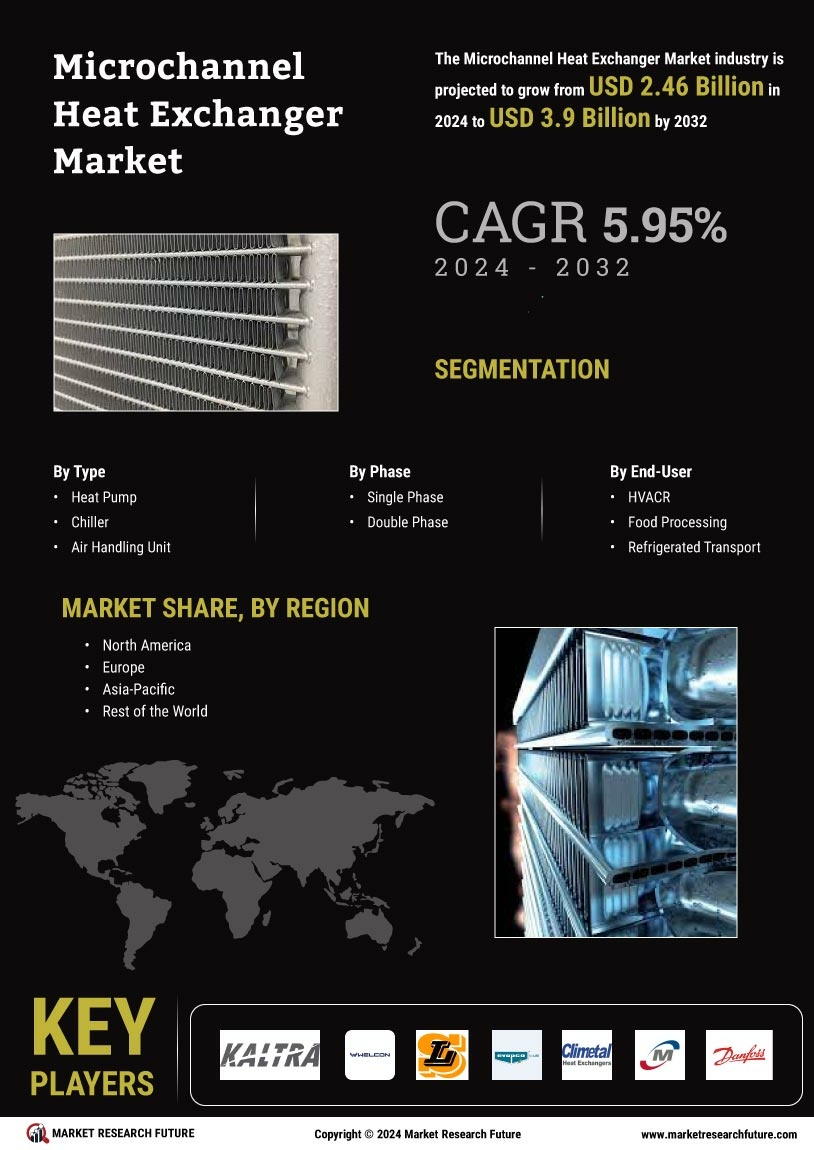

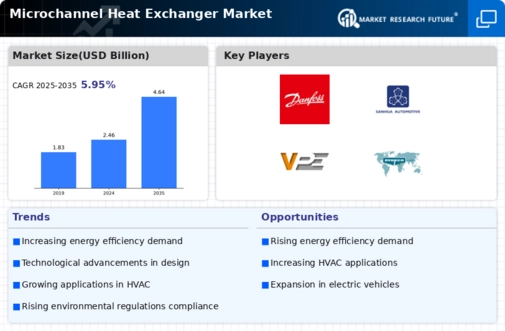

Market Growth Projections

The Global Microchannel Heat Exchanger Market Industry is poised for substantial growth, with projections indicating a market value of 2.46 USD Billion in 2024 and an anticipated increase to 4.64 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 5.93% from 2025 to 2035. Such projections reflect the increasing adoption of microchannel heat exchangers across various sectors, driven by their efficiency and compact design. As industries continue to prioritize energy efficiency and sustainability, the market is likely to expand, presenting opportunities for innovation and development within the microchannel heat exchanger segment.

Technological Advancements

Technological innovations play a pivotal role in shaping the Global Microchannel Heat Exchanger Market Industry. Recent advancements in manufacturing processes and materials have led to the development of more efficient and durable heat exchangers. For example, the introduction of enhanced surface designs and optimized flow configurations has significantly improved heat transfer rates. These innovations not only enhance performance but also reduce the overall size and weight of the units, making them ideal for various applications. As industries continue to adopt these advanced technologies, the market is expected to grow, potentially reaching 4.64 USD Billion by 2035, indicating a robust trajectory for microchannel heat exchangers.

Growth in HVAC Applications

The Global Microchannel Heat Exchanger Market Industry is witnessing substantial growth in the heating, ventilation, and air conditioning (HVAC) sector. The increasing demand for efficient cooling solutions in residential and commercial buildings is driving the adoption of microchannel heat exchangers. These systems offer superior heat transfer capabilities and reduced refrigerant charge, aligning with the industry's push for sustainability. As urbanization accelerates globally, the HVAC market is projected to expand, further propelling the demand for microchannel heat exchangers. This trend is expected to contribute significantly to the market's growth, with a projected CAGR of 5.93% from 2025 to 2035.

Increasing Industrial Applications

The Global Microchannel Heat Exchanger Market Industry is experiencing a notable increase in applications across various industrial sectors, including chemical processing, oil and gas, and food and beverage. The versatility and efficiency of microchannel heat exchangers make them suitable for a wide range of processes, where effective heat transfer is crucial. Industries are increasingly recognizing the benefits of these systems, such as reduced footprint and enhanced thermal performance. As industrial operations strive for greater efficiency and lower operational costs, the demand for microchannel heat exchangers is expected to rise. This trend is indicative of a broader shift towards optimizing industrial processes through advanced thermal management solutions.

Rising Demand for Energy Efficiency

The Global Microchannel Heat Exchanger Market Industry is experiencing a surge in demand driven by the increasing emphasis on energy efficiency across various sectors. Industries are actively seeking solutions that reduce energy consumption and enhance performance. Microchannel heat exchangers, known for their compact design and superior thermal performance, are becoming the preferred choice. For instance, in 2024, the market is projected to reach 2.46 USD Billion, reflecting a growing trend towards sustainable technologies. This shift is further supported by government initiatives promoting energy-efficient systems, which are likely to bolster the adoption of microchannel heat exchangers in the coming years.

Regulatory Support for Environmental Standards

The Global Microchannel Heat Exchanger Market Industry benefits from stringent environmental regulations aimed at reducing greenhouse gas emissions. Governments worldwide are implementing policies that encourage the use of energy-efficient technologies, including microchannel heat exchangers. These regulations not only promote sustainability but also create a favorable environment for manufacturers to innovate and improve their products. For instance, compliance with environmental standards often necessitates the adoption of advanced heat exchangers that minimize energy consumption. As these regulations become more prevalent, the market for microchannel heat exchangers is likely to expand, driven by the need for compliance and the pursuit of greener technologies.