Expansion of the Automotive Electronics Sector

The Sputtering Equipment Cathode Market is also benefiting from the expansion of the automotive electronics sector. As vehicles become increasingly equipped with advanced electronic systems, the demand for high-quality sputtered coatings is on the rise. Sputtering technology is utilized in various automotive applications, including sensors, displays, and electronic control units. The automotive industry is projected to grow steadily, with a significant shift towards electric vehicles (EVs) and autonomous driving technologies. This transition is likely to drive the need for sophisticated sputtering equipment that can meet the stringent requirements of automotive electronics. Consequently, manufacturers in the sputtering equipment cathode market may find new avenues for growth as they align their offerings with the evolving needs of the automotive sector.

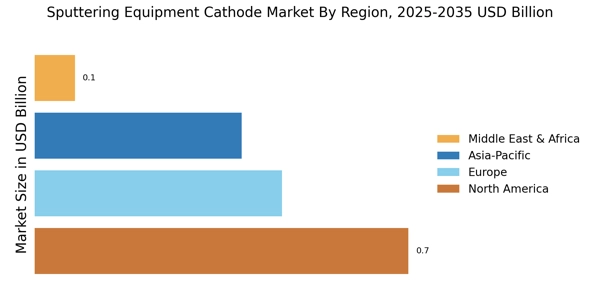

Emerging Markets and Increased Industrialization

The Sputtering Equipment Cathode Market is poised for growth due to the emergence of new markets and increased industrialization in various regions. Countries that are ramping up their manufacturing capabilities are likely to adopt sputtering technology to enhance their production processes. The rise of industries such as consumer electronics, telecommunications, and aerospace in these regions is expected to drive demand for sputtering equipment. Furthermore, as industrialization progresses, there is a growing emphasis on adopting advanced manufacturing techniques, including sputtering, to improve product quality and efficiency. This trend may lead to a broader acceptance of sputtering equipment cathodes, thereby expanding the market reach and creating opportunities for manufacturers to establish a foothold in these developing regions.

Increased Focus on Renewable Energy Technologies

The Sputtering Equipment Cathode Market is witnessing a notable increase in demand driven by the growing focus on renewable energy technologies. Sputtering is essential in the production of thin-film solar cells, which are gaining traction as a sustainable energy solution. The global shift towards clean energy sources is prompting investments in solar technology, thereby enhancing the need for efficient sputtering equipment. Market analysts suggest that the solar energy sector is expected to expand significantly, with projections indicating a potential doubling of installed capacity in the next decade. This trend is likely to create substantial opportunities for sputtering equipment cathode manufacturers, as they cater to the rising demand for high-performance materials in solar applications.

Technological Innovations in Sputtering Equipment

The Sputtering Equipment Cathode Market is experiencing a surge in technological innovations that enhance the efficiency and performance of sputtering processes. Advanced materials and designs are being developed, which improve the deposition rates and uniformity of coatings. For instance, the introduction of high-power impulse magnetron sputtering (HiPIMS) technology has shown potential in achieving superior film qualities. This innovation is likely to attract manufacturers seeking to optimize production processes, thereby driving market growth. Furthermore, the integration of automation and smart technologies into sputtering equipment is expected to streamline operations, reduce costs, and improve overall productivity. As a result, the demand for advanced sputtering equipment cathodes is anticipated to rise, reflecting a broader trend towards modernization in manufacturing practices.

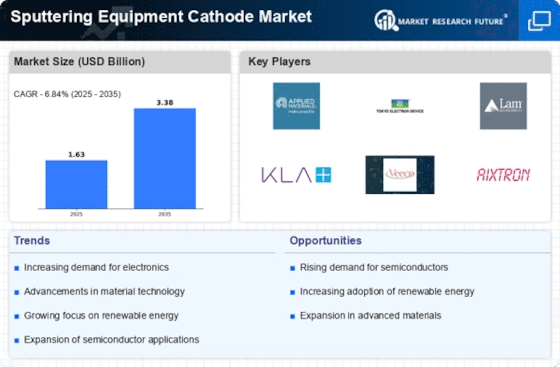

Rising Applications in Semiconductor Manufacturing

The Sputtering Equipment Cathode Market is significantly influenced by the increasing applications of sputtering technology in semiconductor manufacturing. As the semiconductor sector continues to expand, driven by the proliferation of electronic devices, the demand for high-quality thin films is escalating. Sputtering is a preferred method for depositing materials in semiconductor fabrication due to its ability to produce uniform and precise layers. Reports indicate that the semiconductor market is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years, which is likely to bolster the sputtering equipment cathode market. This growth is further supported by the ongoing miniaturization of electronic components, necessitating advanced sputtering techniques to meet stringent performance requirements.