Expansion of End-Use Industries

The expansion of end-use industries is a pivotal factor driving the Specialty Polystyrene Resin Market. As sectors such as construction, healthcare, and consumer goods continue to grow, the demand for specialty polystyrene resins is expected to rise correspondingly. The construction industry, in particular, is increasingly utilizing these resins for insulation and decorative applications, which enhances energy efficiency and aesthetic appeal. Market analysis indicates that the healthcare sector is also adopting specialty polystyrene resins for medical devices and packaging, further diversifying the application landscape. This broadening of end-use industries is likely to sustain the growth momentum of the Specialty Polystyrene Resin Market in the foreseeable future.

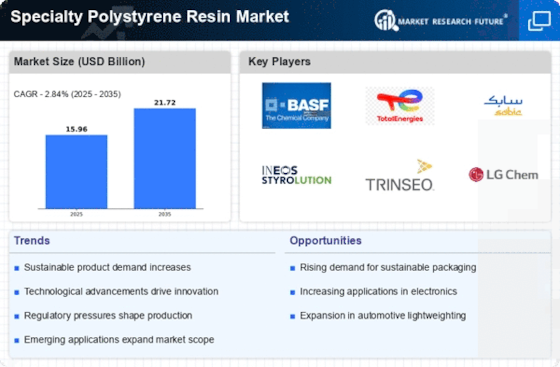

Rising Demand in Packaging Sector

The Specialty Polystyrene Resin Market is experiencing a notable surge in demand, particularly from the packaging sector. This increase is largely attributed to the material's lightweight nature and excellent barrier properties, which make it ideal for food and consumer goods packaging. According to recent data, the packaging segment accounts for a substantial share of the overall market, driven by the need for sustainable and efficient packaging solutions. As consumers become more environmentally conscious, manufacturers are increasingly turning to specialty polystyrene resins that offer recyclability and reduced environmental impact. This trend is expected to continue, with projections indicating that the packaging sector will remain a key driver of growth in the Specialty Polystyrene Resin Market over the coming years.

Innovations in Product Development

Innovations in product development are significantly influencing the Specialty Polystyrene Resin Market. Manufacturers are investing in research and development to create advanced formulations that enhance the performance characteristics of polystyrene resins. These innovations include the development of high-impact and heat-resistant variants, which are increasingly sought after in various applications, including automotive and electronics. The introduction of new grades of specialty polystyrene resins is expected to expand the application scope, thereby attracting a broader customer base. Market data suggests that the introduction of innovative products could lead to a competitive edge for manufacturers, positioning them favorably within the Specialty Polystyrene Resin Market.

Regulatory Support for Sustainable Materials

Regulatory support for sustainable materials is emerging as a critical driver for the Specialty Polystyrene Resin Market. Governments and regulatory bodies are increasingly implementing policies that encourage the use of eco-friendly materials, which aligns with the growing consumer demand for sustainability. This regulatory landscape is fostering innovation and investment in specialty polystyrene resins that meet stringent environmental standards. As a result, manufacturers are motivated to develop products that not only comply with regulations but also appeal to environmentally conscious consumers. The Specialty Polystyrene Resin Market is likely to benefit from these supportive measures, as they create a favorable environment for the adoption of sustainable resin solutions.

Growth in Electronics and Automotive Applications

The Specialty Polystyrene Resin Market is witnessing substantial growth driven by the increasing use of these materials in the electronics and automotive sectors. The lightweight and durable properties of specialty polystyrene resins make them suitable for various applications, including housings, components, and insulation materials. Recent statistics indicate that the electronics sector is projected to grow at a compound annual growth rate (CAGR) of over 5% in the coming years, further propelling the demand for specialty polystyrene resins. Additionally, the automotive industry's shift towards lightweight materials to improve fuel efficiency is likely to bolster the Specialty Polystyrene Resin Market, as manufacturers seek to incorporate these resins into their designs.