South Korea Metal Forging Market Summary

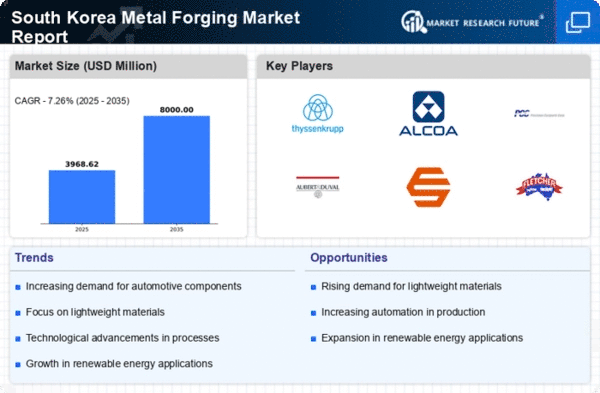

As per Market Research Future analysis, the South Korea metal forging market Size was estimated at 3700.0 USD Million in 2024. The South Korea metal forging market is projected to grow from 3968.62 USD Million in 2025 to 8000.0 USD Million by 2035, exhibiting a compound annual growth rate (CAGR) of 7.2% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The South Korea metal forging market is poised for growth driven by technological advancements and rising demand from key industries.

- Technological advancements are enhancing production efficiency and product quality in the metal forging sector.

- Sustainability initiatives are increasingly influencing manufacturing processes and material selection in the market.

- The automotive sector remains the largest segment, while the aerospace sector is emerging as the fastest-growing segment in South Korea.

- Key market drivers include increasing automotive production and significant investments in infrastructure development initiatives.

Market Size & Forecast

| 2024 Market Size | 3700.0 (USD Million) |

| 2035 Market Size | 8000.0 (USD Million) |

| CAGR (2025 - 2035) | 7.26% |

Major Players

Thyssenkrupp AG (DE), Alcoa Corporation (US), Precision Castparts Corp (US), Aubert & Duval (FR), Forged Solutions Group (GB), Fletcher International (AU), Bharat Forge Limited (IN), Nippon Steel Corporation (JP), Shaanxi Blower (CN)