Growth in Automotive Industry

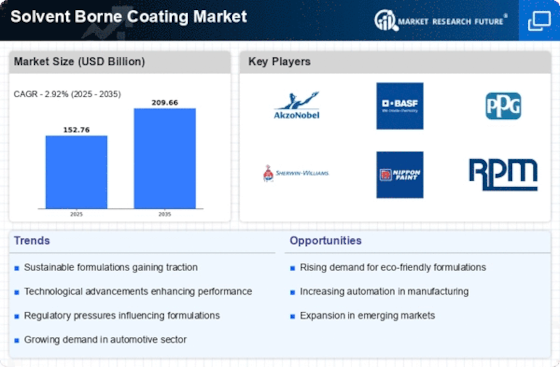

The automotive sector plays a crucial role in the expansion of the Solvent Borne Coating Market. With the automotive industry projected to grow at a compound annual growth rate of around 4.2%, the demand for high-quality coatings is expected to rise correspondingly. Solvent borne coatings are extensively utilized in automotive applications due to their superior finish and protective qualities. They provide excellent resistance to chemicals, UV rays, and corrosion, which are essential for maintaining vehicle aesthetics and longevity. As manufacturers increasingly prioritize quality and performance, the solvent borne coatings segment is likely to benefit from this trend. Additionally, the shift towards electric vehicles may further influence the market, as new coatings are developed to meet the specific requirements of these vehicles, thereby creating new opportunities within the solvent borne coating market.

Increasing Focus on Aesthetic Appeal

The aesthetic appeal of coatings is becoming increasingly important in the Solvent Borne Coating Market. As consumers and businesses alike prioritize visual aspects, the demand for coatings that offer vibrant colors and finishes is on the rise. This trend is particularly evident in sectors such as automotive and interior design, where the appearance of surfaces can significantly influence consumer choices. In 2025, it is estimated that the market for decorative coatings will grow, driven by the desire for unique and customized finishes. Solvent borne coatings are well-suited for this purpose, as they provide a wide range of color options and superior gloss levels. Additionally, the ability to create specialized finishes, such as metallic or matte, further enhances their appeal. Consequently, the focus on aesthetics is likely to propel the growth of the solvent borne coating market, as manufacturers strive to meet evolving consumer preferences.

Rising Demand in Construction Sector

The Solvent Borne Coating Market is experiencing a notable surge in demand, particularly driven by the construction sector. As urbanization accelerates, the need for durable and aesthetically pleasing coatings for buildings and infrastructure becomes paramount. In 2025, the construction industry is projected to grow at a rate of approximately 5.5% annually, which directly influences the consumption of solvent borne coatings. These coatings are favored for their excellent adhesion, durability, and resistance to environmental factors, making them ideal for both interior and exterior applications. Furthermore, the increasing focus on high-performance coatings that can withstand harsh conditions is likely to bolster the market. This trend suggests that the solvent borne coating segment will continue to thrive as construction activities expand, thereby enhancing the overall market landscape.

Technological Innovations in Coating Solutions

Technological advancements are significantly shaping the Solvent Borne Coating Market. Innovations in formulation and application techniques are enhancing the performance characteristics of solvent borne coatings. For instance, the development of low-VOC (volatile organic compounds) formulations is addressing environmental concerns while maintaining the desired properties of traditional solvent borne coatings. In 2025, it is anticipated that the market for low-VOC coatings will account for a substantial share, reflecting a shift towards more sustainable practices. Moreover, advancements in application technologies, such as spray and electrostatic methods, are improving efficiency and reducing waste. These innovations not only enhance the quality of the coatings but also expand their applicability across various sectors, including automotive, construction, and industrial applications. As a result, the solvent borne coating market is likely to witness robust growth driven by these technological improvements.

Regulatory Compliance and Environmental Standards

Regulatory frameworks and environmental standards are increasingly influencing the Solvent Borne Coating Market. Governments worldwide are implementing stricter regulations regarding VOC emissions and environmental impact, prompting manufacturers to adapt their products accordingly. In 2025, compliance with these regulations is expected to drive the demand for low-VOC and eco-friendly solvent borne coatings. This shift not only aligns with The Solvent Borne Coating Market. Companies that invest in developing compliant products are likely to gain a competitive edge, as consumers become more environmentally conscious. Furthermore, adherence to these regulations can enhance brand reputation and customer loyalty. As a result, the solvent borne coating market is poised for growth, driven by the need for compliance and the increasing emphasis on sustainable practices.