Rising Demand for Automotive Tires

The Global Rubber Vulcanization Market Industry experiences a notable surge in demand for automotive tires, driven by the increasing production of vehicles worldwide. As of 2024, the market is valued at approximately 2661.4 USD Billion, reflecting the automotive sector's pivotal role in rubber consumption. The vulcanization process enhances tire durability and performance, making it essential for manufacturers. With the automotive industry projected to grow, the demand for high-quality, vulcanized rubber tires is expected to rise, thereby propelling the overall market. This trend indicates a robust future for the Global Rubber Vulcanization Market, as tire manufacturers seek innovative solutions to meet consumer expectations.

Growth of the Construction Industry

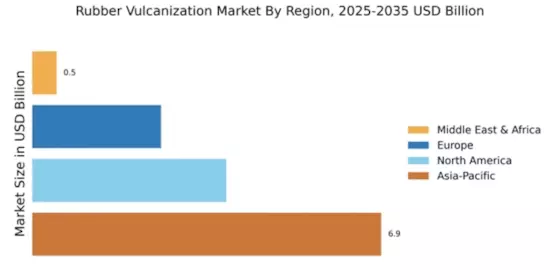

The Global Rubber Vulcanization Market Industry is poised for growth, largely due to the expansion of the construction sector. The increasing demand for durable and resilient materials in construction applications drives the need for vulcanized rubber products, such as seals, gaskets, and flooring. As urbanization accelerates globally, the construction industry is expected to flourish, thereby enhancing the demand for rubber materials. This growth is reflected in the projected market value of 4367.3 USD Billion by 2035, indicating a sustained interest in high-performance rubber solutions. Consequently, the vulcanization process becomes crucial in meeting the rigorous demands of the construction sector.

Emerging Markets and Economic Growth

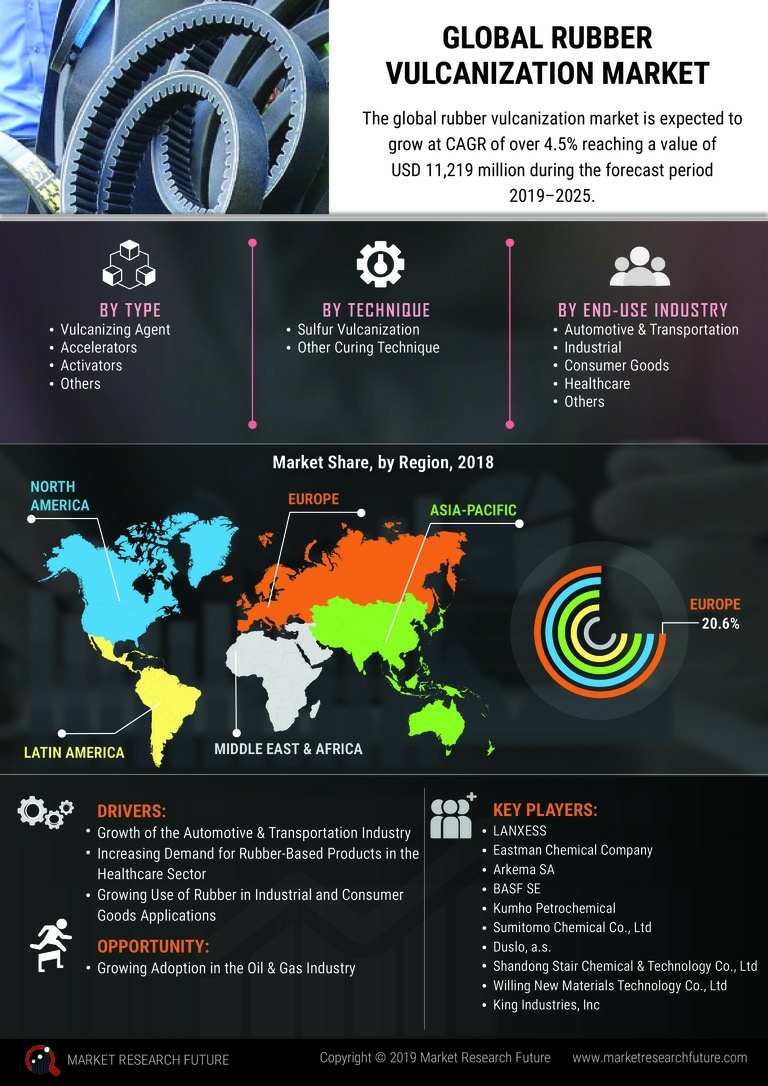

Emerging markets are playing a pivotal role in shaping the Global Rubber Vulcanization Market Industry. Countries in Asia-Pacific and Latin America are experiencing rapid economic growth, leading to increased industrialization and urbanization. This growth drives the demand for rubber products across various sectors, including automotive, construction, and consumer goods. As these economies expand, the market is expected to grow at a compound annual growth rate (CAGR) of 4.61% from 2025 to 2035. This trend indicates a robust potential for the vulcanization industry as manufacturers seek to establish a presence in these burgeoning markets, capitalizing on the rising demand for high-quality rubber products.

Technological Advancements in Rubber Processing

Technological advancements in rubber processing techniques are significantly influencing the Global Rubber Vulcanization Market Industry. Innovations such as improved mixing technologies and advanced curing methods enhance the efficiency and quality of vulcanized rubber products. These advancements not only reduce production costs but also improve the performance characteristics of rubber, making it more appealing to various industries. As manufacturers adopt these technologies, they can produce higher-quality products that meet stringent regulatory standards. This trend suggests a promising growth trajectory for the market, as companies leverage technology to gain a competitive edge and cater to evolving consumer demands.

Environmental Regulations and Sustainability Initiatives

The Global Rubber Vulcanization Market Industry is increasingly influenced by stringent environmental regulations and sustainability initiatives. Governments worldwide are implementing policies aimed at reducing carbon footprints and promoting eco-friendly materials. As a result, manufacturers are compelled to adopt sustainable practices in rubber production, including the use of recycled materials and eco-friendly vulcanization processes. This shift not only aligns with regulatory requirements but also caters to the growing consumer preference for sustainable products. Consequently, the market is likely to witness a transformation as companies innovate to meet these environmental standards, thereby enhancing their market position.