Expansion of the E-commerce Sector

The rapid expansion of the e-commerce sector significantly influences the Global Rotogravure Printing Inks Market Industry. With the rise of online shopping, there is an increasing need for packaging that ensures product safety during transit while also appealing to consumers. Rotogravure printing inks are favored for their ability to produce high-quality images and branding on packaging materials. This trend is expected to drive market growth, as the e-commerce industry continues to flourish. Projections indicate that by 2035, the market could reach 7.2 USD Billion, reflecting the growing importance of effective packaging solutions in online retail.

Rising Demand for Sustainable Inks

The Global Rotogravure Printing Inks Market Industry is witnessing a shift towards sustainable ink formulations. As environmental concerns become more pronounced, manufacturers are increasingly seeking inks that are eco-friendly and compliant with regulations. Water-based and solvent-free inks are gaining traction, as they reduce harmful emissions and promote sustainability. This trend aligns with global efforts to minimize environmental impact, and companies that adopt sustainable practices may gain a competitive edge. The market's growth is likely to be bolstered by this demand for greener alternatives, as consumers and businesses alike prioritize sustainability in their purchasing decisions.

Growing Demand for Flexible Packaging

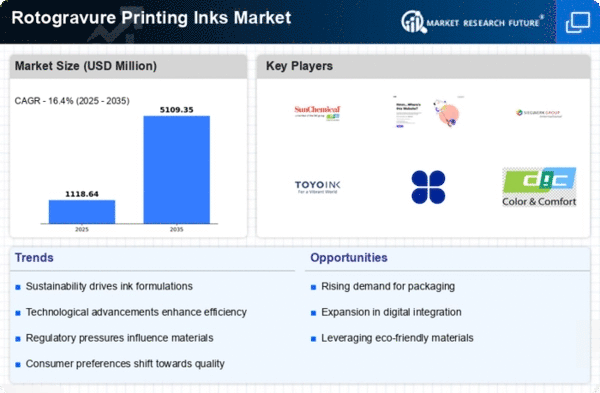

The Global Rotogravure Printing Inks Market Industry experiences a notable surge in demand for flexible packaging solutions. This trend is driven by the increasing consumer preference for lightweight, easy-to-handle packaging materials that maintain product freshness. Flexible packaging is often utilized in food and beverage sectors, where rotogravure printing inks provide high-quality graphics and vibrant colors. As of 2024, the market is projected to reach 4.07 USD Billion, reflecting the industry's adaptation to consumer needs. The shift towards sustainable packaging options further enhances the growth potential, as manufacturers seek inks that align with eco-friendly practices.

Increased Investment in Packaging Solutions

Investment in innovative packaging solutions is a driving force behind the Global Rotogravure Printing Inks Market Industry. Companies are allocating resources to develop packaging that not only protects products but also enhances brand visibility. Rotogravure printing inks are integral to achieving high-quality graphics and intricate designs that attract consumers. As brands strive to differentiate themselves in a competitive marketplace, the demand for advanced packaging solutions is expected to rise. This trend may contribute to a compound annual growth rate of 5.31% from 2025 to 2035, reflecting the industry's commitment to innovation and quality.

Technological Advancements in Printing Processes

Technological innovations play a pivotal role in shaping the Global Rotogravure Printing Inks Market Industry. Advancements in printing technologies, such as digital integration and automation, enhance the efficiency and quality of rotogravure printing. These innovations allow for faster production times, reduced waste, and improved color consistency. As companies invest in modern printing equipment, the demand for high-performance inks that can withstand these processes increases. This trend is likely to contribute to the market's growth, as manufacturers seek to optimize their operations and meet the evolving demands of consumers.