North America : Innovation and Demand Surge

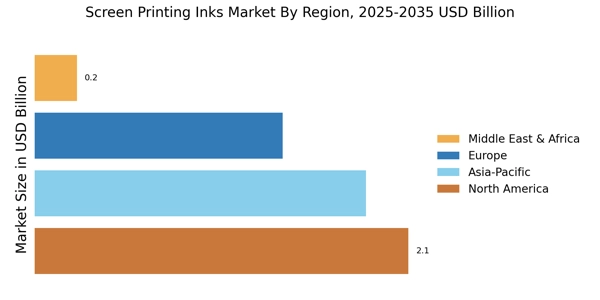

The North American screen printing inks market is driven by a surge in demand from the packaging and textile industries, with the U.S. holding the largest market share at approximately 45%. Regulatory support for sustainable practices is also a key catalyst, as companies increasingly adopt eco-friendly inks. The region is witnessing a shift towards digital printing technologies, enhancing efficiency and reducing waste.

Leading the screen printing ink market are the U.S. and Canada, with significant contributions from major players like Sun Chemical and Nazdar Ink Technologies. The competitive landscape is characterized by innovation and strategic partnerships, as companies invest in R&D to develop advanced ink formulations. The presence of established firms ensures a robust supply chain, catering to diverse applications across various sectors.

Europe : Sustainability and Innovation Focus

Europe is emerging as a significant player in the screen printing inks market, driven by stringent environmental regulations and a growing demand for sustainable products. The region holds the second-largest market share, accounting for around 30%. Countries like Germany and the UK are at the forefront, with regulations promoting the use of low-VOC inks and sustainable practices, fostering innovation in the industry.

Germany leads the screen printing ink market, supported by key players such as Marabu GmbH and Fujifilm Sericol. The competitive landscape is marked by a focus on eco-friendly solutions, with companies investing in research to develop inks that meet regulatory standards. The presence of a well-established manufacturing base and a strong distribution network further enhances market growth, positioning Europe as a leader in sustainable printing solutions.

Asia-Pacific : Rapid Growth and Expansion

The Asia-Pacific region is witnessing rapid growth in the screen printing inks market, driven by increasing industrialization and urbanization. Countries like China and India are leading this expansion, with China holding the largest market share at approximately 40%. The demand for screen printing inks is fueled by the booming packaging and textile sectors, alongside supportive government initiatives promoting manufacturing and exports.

China and Japan are the dominant players, with significant contributions from companies like Sakata INX and Toyo Ink SC Holdings. The competitive landscape is characterized by a mix of local and international players, focusing on innovation and cost-effective solutions. The region's growing middle class and rising disposable incomes are further driving demand for printed products, enhancing market prospects.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region is gradually emerging as a potential market for screen printing inks, driven by increasing demand in the packaging and advertising sectors. The market is still developing, with a share of around 10%, but countries like South Africa and the UAE are showing promising growth trends. Regulatory frameworks are evolving, encouraging the adoption of modern printing technologies and sustainable practices.

South Africa is leading the market, supported by local manufacturers and international players looking to expand their footprint. The competitive landscape is characterized by a mix of established companies and new entrants, focusing on innovation and quality. As the region continues to develop economically, the demand for screen printing inks is expected to rise, presenting opportunities for growth and investment.