Rising Demand for Efficiency

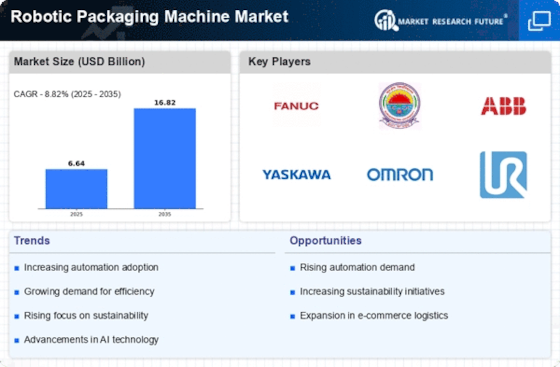

The Robotic Packaging Machine Market is experiencing a notable surge in demand for efficiency across various sectors. Companies are increasingly seeking to optimize their production processes, thereby reducing operational costs and enhancing throughput. This trend is particularly evident in the food and beverage sector, where the need for rapid packaging solutions is paramount. According to recent data, the market for robotic packaging machines is projected to grow at a compound annual growth rate of approximately 10% over the next five years. This growth is driven by the necessity for manufacturers to maintain competitive advantage through improved efficiency and reduced labor costs, which robotic solutions can effectively provide.

Evolving Consumer Preferences

The Robotic Packaging Machine Market is adapting to evolving consumer preferences that demand faster and more customized packaging solutions. As consumers increasingly seek personalized products, manufacturers are compelled to innovate their packaging processes. Robotic packaging machines facilitate this customization by allowing for flexible production lines that can quickly switch between different packaging formats. This adaptability is crucial in industries such as cosmetics and electronics, where product variations are common. The market is projected to expand as companies invest in robotic technologies to meet these changing demands, with a focus on enhancing customer satisfaction and brand loyalty.

Technological Advancements in Robotics

The Robotic Packaging Machine Market is benefiting from rapid technological advancements in robotics and automation. Innovations such as artificial intelligence, machine learning, and advanced sensors are enhancing the capabilities of robotic packaging machines. These technologies enable machines to perform complex tasks with greater precision and efficiency, thereby improving overall productivity. The integration of smart technologies allows for real-time monitoring and data analysis, which can lead to further optimization of packaging processes. As these advancements continue to evolve, the market is likely to see increased adoption of sophisticated robotic solutions, driving growth and enhancing operational capabilities.

Labor Shortages and Workforce Challenges

The Robotic Packaging Machine Market is significantly influenced by ongoing labor shortages and challenges in workforce management. Many industries are grappling with difficulties in hiring and retaining skilled labor, prompting a shift towards automation. Robotic packaging machines offer a viable solution to mitigate these challenges by providing consistent performance and reliability. As companies face increasing pressure to maintain production levels, the adoption of robotic solutions is likely to rise. This trend is particularly pronounced in sectors such as pharmaceuticals and consumer goods, where precision and speed are critical. The market is expected to respond positively to this shift, with an anticipated increase in investments in robotic technologies.

Regulatory Compliance and Safety Standards

The Robotic Packaging Machine Market is increasingly shaped by stringent regulatory compliance and safety standards. As industries face heightened scrutiny regarding product safety and quality, the demand for automated packaging solutions that adhere to these regulations is on the rise. Robotic packaging machines are designed to meet various safety standards, ensuring that products are packaged in a manner that minimizes contamination and maximizes quality. This trend is particularly relevant in the food and pharmaceutical sectors, where compliance is critical. The market is expected to grow as companies prioritize investments in robotic technologies that not only enhance efficiency but also ensure adherence to regulatory requirements.