Rigid Packaging Size

Rigid Packaging Market Growth Projections and Opportunities

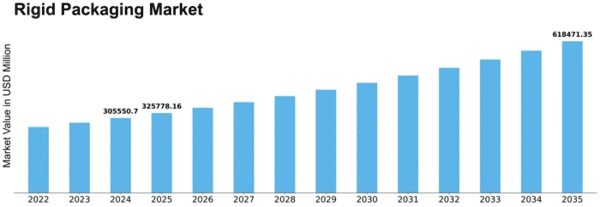

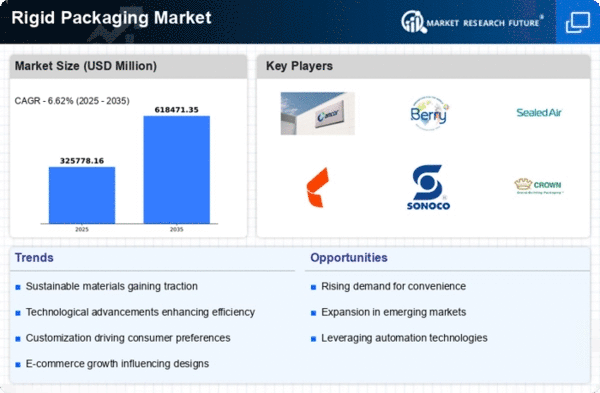

The rigid packaging industry is expected to grow from USD 271,682.7 million in 2022 to USD 430586.9 million in 2030, a 6.8% CAGR.

The rigid packaging market, a vital part of the packaging industry, is shaped by many market forces. Customers want comfort, management, and item protection as their lifestyles change, which rigid packaging provides.

The rigid packaging market is boosted by food and beverage. Because consumables need sturdy and protective packaging to stay fresh, rigid packaging arrangements are becoming more common. Plastic, glass, and metal offer unmatched obstructive properties, preventing contamination and extending product usability. In addition, the growing trend of fast use has increased demand for lightweight and compact rigid packaging like PET jugs and useful, resealable compartments.

Rising awareness and emphasis on sustainable packaging solutions also affects the rigid packaging sector. When managed, rigid packaging can be environmentally friendly. Producers are responding to this interest by introducing reused or recyclable packaging, which reduces the natural look.

Administrative actions and rules shape the rigid packaging business. Sanitation, product detectability, and natural effect are being addressed by strict laws and international organizations. Market players must follow these criteria to ensure packaging quality and safety. Boundary coatings and smart packaging solutions that improve product security and visibility have advanced due to this.

The rigid packaging market is also affected by retail and buyer preferences. As online company grows, so does demand for packaging that protects products throughout shipping. The uprightness of rigid packaging protects things during transportation. The rise of online business has also increased the focus on stylish and interesting packaging to improve the customer unpacking experience.

Raw costs of materials and accessibility also shape the rigid packaging market. Plastics, metals, and glass price fluctuations have a direct impact on packaging manufacturers' production costs. International events and retail network disruptions might influence the availability of unprocessed substances, which can hurt the firm. Market players must use elective obtaining and effective store network executives to reduce the impact of these variables on production costs."

Leave a Comment