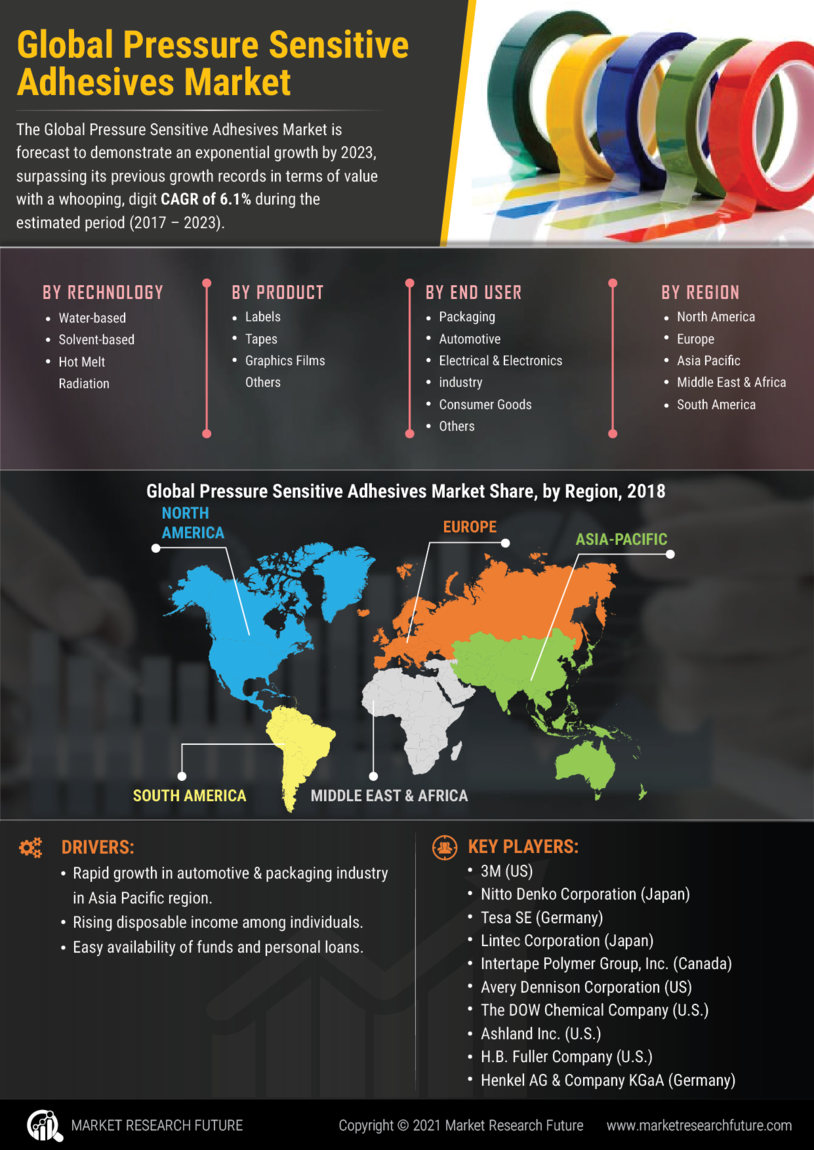

Rising Automotive Sector

The automotive sector's expansion significantly impacts the Global Pressure Sensitive Adhesives Market Industry. As manufacturers seek lightweight materials to enhance fuel efficiency and reduce emissions, pressure sensitive adhesives are increasingly utilized in vehicle assembly and interior applications. These adhesives offer advantages such as improved bonding and reduced weight, which are crucial in modern automotive design. The growing trend towards electric vehicles further amplifies this demand, as manufacturers prioritize innovative materials to meet performance standards. Consequently, the automotive industry's growth trajectory is likely to bolster the Global Pressure Sensitive Adhesives Market Industry, creating new opportunities for manufacturers and suppliers alike.

Market Growth Projections

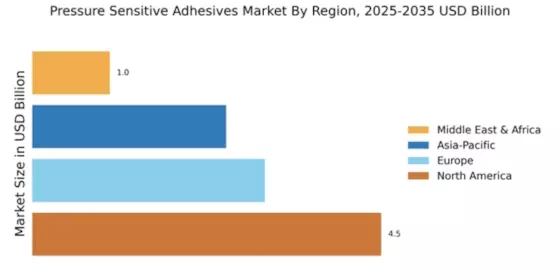

The Global Pressure Sensitive Adhesives Market Industry is poised for substantial growth, with projections indicating a market size of 9.52 USD Billion in 2024 and an anticipated increase to 19.7 USD Billion by 2035. This growth trajectory reflects a compound annual growth rate of 6.82% from 2025 to 2035. Such projections underscore the increasing adoption of pressure sensitive adhesives across various sectors, driven by technological advancements and evolving consumer preferences. The market's expansion is likely to create new opportunities for manufacturers, suppliers, and end-users alike, highlighting the dynamic nature of the Global Pressure Sensitive Adhesives Market Industry.

Growing Demand in Packaging Industry

The Global Pressure Sensitive Adhesives Market Industry experiences a robust demand surge, particularly from the packaging sector. As consumer preferences shift towards convenient and sustainable packaging solutions, manufacturers are increasingly adopting pressure sensitive adhesives for their versatility and efficiency. This trend is evident as the market is projected to reach 9.52 USD Billion in 2024, driven by innovations in adhesive formulations that enhance performance. The rise in e-commerce and online shopping further propels this demand, as packaging plays a crucial role in product protection and presentation. Consequently, the packaging industry's growth significantly influences the expansion of the Global Pressure Sensitive Adhesives Market Industry.

Diverse Applications Across Industries

The versatility of pressure sensitive adhesives is a significant driver of the Global Pressure Sensitive Adhesives Market Industry. These adhesives find applications across various sectors, including healthcare, electronics, and construction. In healthcare, for instance, pressure sensitive adhesives are used in medical tapes and wound dressings, ensuring patient comfort and safety. In electronics, they are essential for bonding components and enhancing product durability. The construction industry also utilizes these adhesives for flooring and insulation applications. This diversity in applications not only broadens the market's reach but also fosters innovation, as manufacturers continuously seek to develop specialized products tailored to specific industry needs.

Increased Focus on Sustainable Solutions

The Global Pressure Sensitive Adhesives Market Industry is witnessing a paradigm shift towards sustainability. As environmental concerns gain prominence, manufacturers are increasingly focusing on developing eco-friendly adhesive solutions. This shift is driven by regulatory pressures and consumer preferences for sustainable products. The introduction of bio-based and recyclable adhesives not only meets these demands but also enhances brand loyalty among environmentally conscious consumers. Companies that prioritize sustainability are likely to gain a competitive edge in the market. This trend is expected to contribute to the overall growth of the Global Pressure Sensitive Adhesives Market Industry, as sustainability becomes a key differentiator in product offerings.

Technological Advancements in Adhesive Formulations

Technological advancements in adhesive formulations are pivotal in shaping the Global Pressure Sensitive Adhesives Market Industry. Innovations such as the development of eco-friendly and high-performance adhesives are gaining traction. These advancements not only improve adhesion properties but also cater to environmental regulations, appealing to a broader consumer base. For instance, the introduction of water-based and solvent-free adhesives aligns with sustainability goals, thus enhancing market appeal. As the industry evolves, these technological improvements are expected to contribute to the market's growth trajectory, with projections indicating a rise to 19.7 USD Billion by 2035, reflecting a compound annual growth rate of 6.82% from 2025 to 2035.