Growing Focus on Asset Longevity

The growing focus on asset longevity is increasingly shaping the Predictive Maintenance Market. Organizations are recognizing that extending the lifespan of equipment not only reduces capital expenditures but also enhances overall productivity. Predictive maintenance strategies enable companies to monitor asset conditions and perform maintenance activities at optimal times, thereby maximizing asset utilization. Research suggests that businesses employing predictive maintenance can extend equipment life by up to 20%. This emphasis on asset longevity is likely to drive further investments in predictive maintenance technologies, as companies seek to optimize their asset management strategies.

Advancements in Sensor Technologies

Advancements in sensor technologies are playing a pivotal role in the evolution of the Predictive Maintenance Market. The proliferation of low-cost, high-performance sensors enables organizations to collect real-time data on equipment performance and health. These sensors facilitate continuous monitoring, allowing for timely interventions before failures occur. The market for industrial sensors is projected to reach USD 30 billion by 2027, indicating a robust growth trajectory. As sensor technologies continue to improve, the Predictive Maintenance Market is expected to benefit from enhanced data accuracy and reliability, further driving adoption.

Integration of Artificial Intelligence

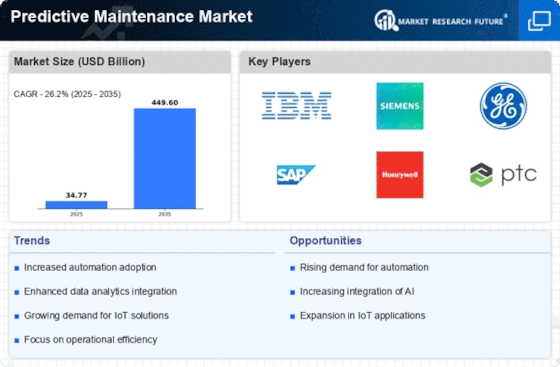

The integration of artificial intelligence (AI) technologies into the Predictive Maintenance Market is transforming how organizations approach maintenance strategies. AI algorithms analyze vast amounts of data from machinery and equipment, identifying patterns that may indicate potential failures. This proactive approach not only minimizes downtime but also optimizes maintenance schedules, leading to cost savings. According to recent estimates, the AI segment within the predictive maintenance sector is expected to grow at a compound annual growth rate (CAGR) of over 30% through 2026. As industries increasingly adopt AI-driven solutions, the Predictive Maintenance Market is likely to witness enhanced efficiency and reliability in operations.

Rising Demand for Operational Efficiency

The relentless pursuit of operational efficiency is a primary driver in the Predictive Maintenance Market. Organizations are increasingly recognizing that predictive maintenance can significantly reduce operational costs by preventing unexpected equipment failures. By leveraging predictive analytics, companies can schedule maintenance activities during non-peak hours, thereby minimizing disruptions. Reports indicate that businesses implementing predictive maintenance strategies can achieve up to a 25% reduction in maintenance costs. This growing demand for efficiency is propelling investments in predictive maintenance technologies, further solidifying the market's expansion.

Regulatory Compliance and Safety Standards

Regulatory compliance and adherence to safety standards are critical factors influencing the Predictive Maintenance Market. Industries such as manufacturing, energy, and transportation are subject to stringent regulations that mandate regular equipment inspections and maintenance. Predictive maintenance solutions help organizations meet these compliance requirements by providing real-time monitoring and reporting capabilities. As regulatory bodies increasingly emphasize the importance of safety and reliability, the demand for predictive maintenance solutions is expected to rise. This trend is likely to drive market growth as companies seek to avoid penalties and enhance their safety records.