Growth in Robotics and Automation

The Precision Gearbox Machinery Market is significantly influenced by the rapid growth in robotics and automation technologies. As industries adopt automation to enhance productivity and reduce labor costs, the demand for precision gearboxes in robotic applications is on the rise. Robotics applications require gearboxes that provide high torque and precision, which are essential for tasks ranging from assembly to material handling. Market analysis indicates that the robotics sector is expected to grow at a CAGR of over 10% in the next few years, further propelling the Precision Gearbox Machinery Market. This growth is indicative of a broader trend towards automation across various sectors, including manufacturing, healthcare, and logistics.

Expansion of Renewable Energy Sector

The Precision Gearbox Machinery Market is poised to gain momentum from the expansion of the renewable energy sector. As the world shifts towards sustainable energy sources, the demand for precision gearboxes in wind turbines and solar tracking systems is increasing. These applications require gearboxes that can operate efficiently under varying loads and conditions. Recent estimates suggest that the renewable energy sector could see investments exceeding $1 trillion in the coming years, which will likely drive the need for advanced precision gearboxes. This trend not only supports the growth of the Precision Gearbox Machinery Market but also aligns with global efforts to reduce carbon emissions and promote sustainable practices.

Rising Demand for Precision Engineering

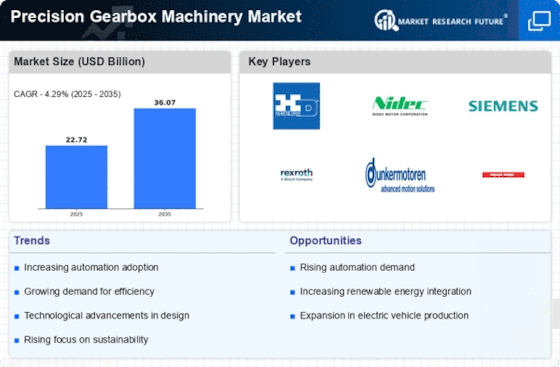

The Precision Gearbox Machinery Market is experiencing a notable surge in demand due to the increasing need for precision engineering across various sectors. Industries such as aerospace, automotive, and robotics are increasingly relying on precision gearboxes to enhance performance and efficiency. According to recent data, the demand for precision gearboxes is projected to grow at a compound annual growth rate of approximately 6% over the next five years. This growth is driven by the need for high-accuracy components that can withstand extreme conditions while maintaining operational reliability. As manufacturers strive to meet stringent quality standards, the Precision Gearbox Machinery Market is likely to benefit from this trend, leading to innovations in design and manufacturing processes.

Technological Innovations in Gearbox Design

The Precision Gearbox Machinery Market is witnessing a wave of technological innovations that are transforming gearbox design and functionality. Advances in materials science and engineering are enabling the development of lighter, stronger, and more efficient gearboxes. Innovations such as 3D printing and computer-aided design are facilitating the creation of customized solutions that meet specific application requirements. As industries demand more efficient and reliable machinery, the Precision Gearbox Machinery Market is likely to see an influx of new products that leverage these technologies. This trend not only enhances the performance of precision gearboxes but also contributes to the overall competitiveness of manufacturers in a rapidly evolving market.

Increasing Investment in Manufacturing Technologies

The Precision Gearbox Machinery Market is benefiting from increasing investments in advanced manufacturing technologies. As companies seek to enhance operational efficiency and reduce production costs, there is a growing emphasis on integrating precision gearboxes into manufacturing processes. The adoption of technologies such as additive manufacturing and Industry 4.0 is driving the need for high-performance gearboxes that can support complex machinery. Recent reports indicate that investments in manufacturing technologies are expected to reach $500 billion by 2026, which will likely bolster the Precision Gearbox Machinery Market. This trend reflects a broader commitment to innovation and efficiency in manufacturing, positioning precision gearboxes as critical components in modern production systems.