Research Methodology on Industrial Gearbox Market

Abstract

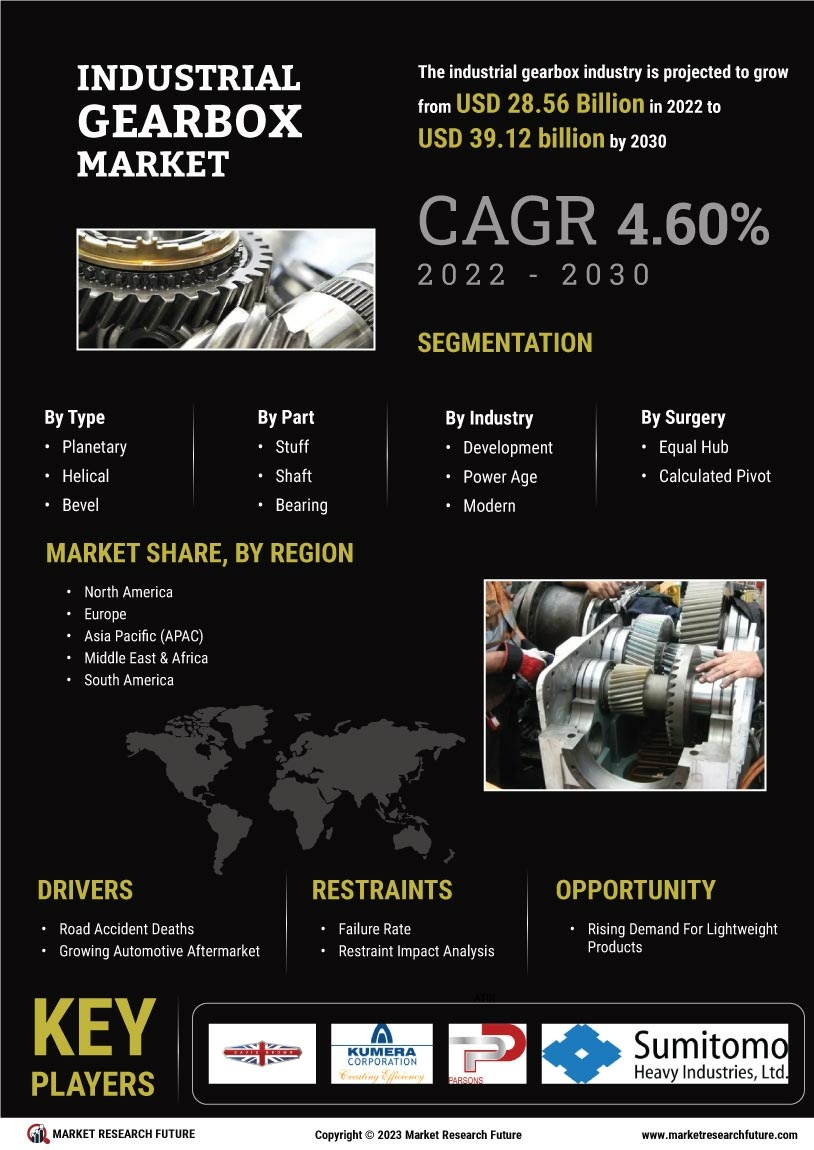

This research paper discusses the market analysis, drivers and restraints, and the growth factors of the Industrial Gearbox Market. A detailed analysis of the current market trends, current and future demands and technological advancements is made to form a comprehensive understanding of the market. A thorough SWOT analysis and Porter’s 5 forces analysis are used to understand the potential threats and opportunities of the market. The top key players dominating the market are mentioned along with their financial and business strategies adopted by them.

Introduction

An industrial gearbox is an electromechanical device that combines different types of mechanical gears to transmit power from a prime mover to an output load. It changes the speed of the input load to generate torque and operate at different speeds and positions. Industrial gearboxes are a vital component in many industrial processes and are used to improve efficiency and ensure safety. The increase in industrial manufacturing and demand for process automation has led to increased demand and investments in industrial gearboxes. This has created many growth opportunities in this sector, which has further led to the considerable growth of the global industrial gearbox market.

Research Methodology

This research includes qualitative and quantitative aspects of the Industrial Gearbox Market, in order to form an overall assessment of the market. Primary and secondary methods are used to form comprehensive insights into the latest developments and trends in the market. An extensive exploration of the market is conducted to gauge the volume and market size of the Industrial Gearbox Market, worldwide.

Primary Research

Primary research is based on data collection from direct sources. Data gathered from interviews and surveys conducted among opinion makers and industry experts are used as primary sources. The interviewers discussed the topics related to the market to gain better insights into the market. Information-rich sources such as industry analysis reports are also employed to analyze the market in greater depth. The data from the primary sources is then verified and validated to ensure accuracy.

Secondary Research

Secondary research includes data collection from sources such as journal articles, market reports, company websites and online survey reports. Secondary sources are used to evaluate the market size and volume of the Industrial Gearbox Market. A thorough exploration of the competitive landscape, market size, share and technology advancements is also conducted using secondary research methods.

Market Modelling

The market size and share of the Industrial Gearbox Market are estimated using market modelling techniques such as bottom-up and top-down approaches. The data gathered from both primary and secondary sources are used to arrive at the final market size and share. The data is further validated with the help of primary interviews and validated by industry experts.

Data Triangulation

Data triangulation is carried out to analyze and validate the market size and understand the various applications of the Industrial Gearbox Market. Information obtained from various sources is collected, analyzed and validated to calculate the total market size.

Market Estimation

The market size and share of the Industrial Gearbox Market are estimated by considering the global market value, total unit sales of the product, price of the product and income generated by the Key Players. The data is further validated with the help of interviews and surveys conducted among opinion makers and industry experts.

Conclusion

The research studies are conducted to provide a comprehensive understanding of the Industrial Gearbox Market. The analysis includes an in-depth understanding of the market size and share, trends, Drivers and Restraints, technology advancements and growth potentials. Data from primary and secondary sources are used to form an overall assessment of the market and its future projections. The report serves as a valuable research tool for industry players, investors and market researchers and also provides insights into the current trends and growth potentials of the market.