Rising Demand for Automation

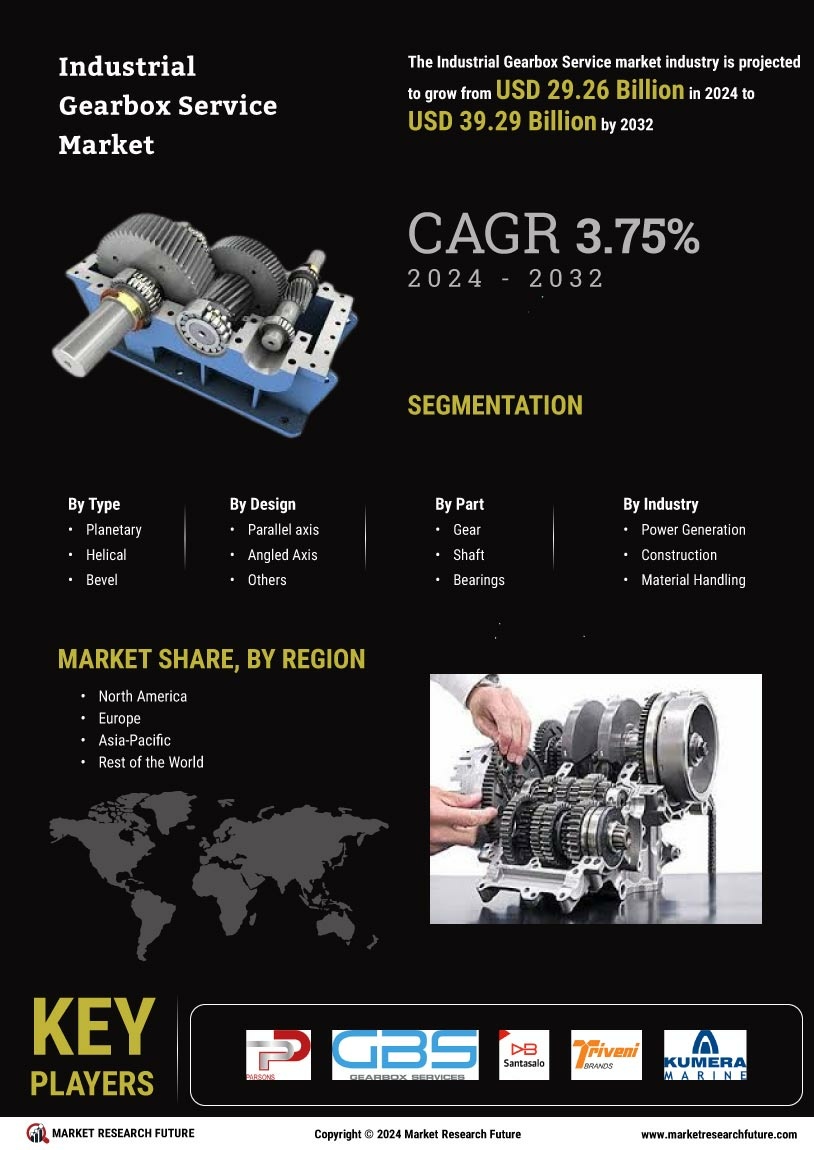

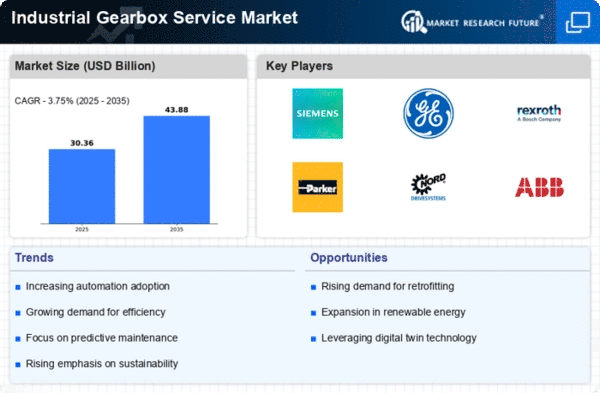

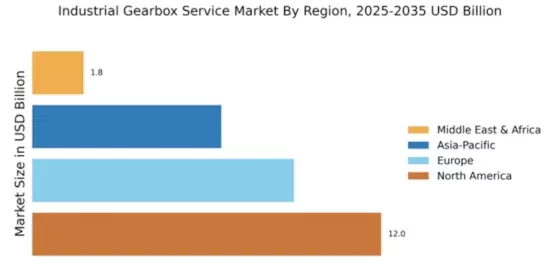

The Global Industrial Gearbox Service Market Industry experiences a notable surge in demand for automation across various sectors, including manufacturing and energy. As industries increasingly adopt automated systems to enhance efficiency and productivity, the need for reliable gearboxes becomes paramount. This trend is particularly evident in the manufacturing sector, where automated machinery relies heavily on high-performance gearboxes. The market is projected to reach 29.3 USD Billion in 2024, driven by this growing reliance on automation. Furthermore, the shift towards smart factories and Industry 4.0 initiatives is likely to further bolster the demand for advanced gearbox services.

Expansion of Renewable Energy Sector

The Global Industrial Gearbox Service Market Industry is significantly influenced by the expansion of the renewable energy sector. As countries worldwide prioritize sustainable energy sources, the demand for wind and solar power has surged. Wind turbines, which rely on specialized gearboxes for optimal performance, are particularly critical in this transition. The increasing installation of wind farms globally necessitates regular gearbox maintenance and servicing, thereby driving market growth. By 2035, the market is expected to grow to 43.9 USD Billion, reflecting the importance of gearbox services in supporting renewable energy infrastructure.

Focus on Preventive Maintenance Strategies

The Global Industrial Gearbox Service Market Industry is increasingly influenced by a focus on preventive maintenance strategies. Industries are recognizing the importance of regular maintenance to prevent unexpected failures and costly downtimes. This proactive approach not only enhances the reliability of machinery but also extends the lifespan of gearboxes. Companies are investing in advanced monitoring technologies to predict maintenance needs accurately. As a result, the demand for gearbox servicing is likely to rise, reflecting a shift towards more sustainable operational practices. This trend aligns with the overall growth expectations for the market in the coming years.

Technological Advancements in Gearbox Design

Technological advancements in gearbox design play a crucial role in shaping the Global Industrial Gearbox Service Market Industry. Innovations such as improved materials, enhanced lubrication systems, and advanced manufacturing techniques contribute to the development of more efficient and durable gearboxes. These advancements not only extend the lifespan of gearboxes but also reduce maintenance costs, making them more appealing to industries. As companies seek to optimize their operations, the demand for high-quality gearbox services is likely to increase. The anticipated CAGR of 3.75% from 2025 to 2035 underscores the market's potential growth driven by these technological innovations.

Increasing Industrialization in Emerging Economies

The Global Industrial Gearbox Service Market Industry is witnessing growth due to increasing industrialization in emerging economies. Countries such as India and Brazil are experiencing rapid industrial growth, leading to heightened demand for industrial machinery and equipment. This growth necessitates the use of gearboxes in various applications, from manufacturing to transportation. As these economies continue to develop, the need for reliable gearbox services becomes more pronounced. The market's expansion in these regions is expected to contribute significantly to the overall growth trajectory, aligning with the projected figures for the coming years.