Technological Innovations

Technological innovations are reshaping the landscape of the Polypropylene Honeycomb Market. Advances in manufacturing processes, such as improved molding techniques and enhanced material formulations, are leading to higher quality products with superior performance characteristics. These innovations not only increase the strength-to-weight ratio of polypropylene honeycomb but also reduce production costs. As a result, the market is likely to experience a surge in demand from sectors such as automotive and construction, where lightweight and durable materials are essential. The integration of smart technologies into production processes may further enhance the efficiency and sustainability of the Polypropylene Honeycomb Market.

Sustainability Initiatives

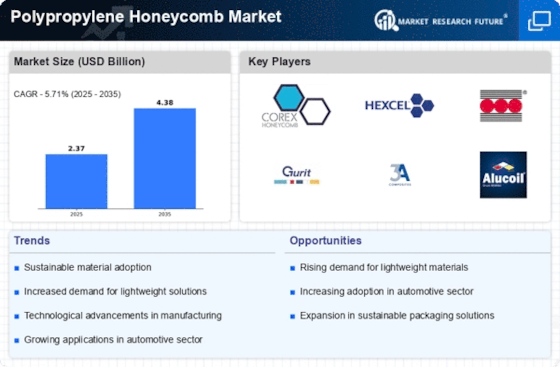

The increasing emphasis on sustainability appears to be a pivotal driver for the Polypropylene Honeycomb Market. As industries strive to reduce their carbon footprints, the demand for eco-friendly materials has surged. Polypropylene honeycomb, being recyclable and lightweight, aligns well with these sustainability goals. In 2025, the market is projected to witness a growth rate of approximately 5% annually, driven by the rising preference for sustainable packaging and construction materials. Companies are increasingly adopting polypropylene honeycomb solutions to meet regulatory requirements and consumer expectations for environmentally responsible products. This trend not only enhances brand reputation but also opens new avenues for innovation within the Polypropylene Honeycomb Market.

Customization and Versatility

Customization and versatility are emerging as critical factors propelling the Polypropylene Honeycomb Market. The ability to tailor products to specific applications, such as automotive, aerospace, and construction, is becoming increasingly important. In 2025, the market is expected to expand as manufacturers offer a wider range of sizes, shapes, and colors to meet diverse customer needs. This adaptability allows for enhanced performance in various applications, making polypropylene honeycomb an attractive choice for designers and engineers. The growing trend towards personalized solutions indicates a shift in consumer preferences, further driving the demand within the Polypropylene Honeycomb Market.

Growing Demand in Automotive Sector

The automotive sector's growing demand for lightweight materials is significantly influencing the Polypropylene Honeycomb Market. As manufacturers seek to improve fuel efficiency and reduce emissions, the adoption of lightweight components has become a priority. Polypropylene honeycomb, known for its excellent strength-to-weight ratio, is increasingly utilized in vehicle interiors, exteriors, and structural applications. In 2025, the automotive industry is projected to account for a substantial share of the polypropylene honeycomb market, driven by stringent regulations and consumer preferences for eco-friendly vehicles. This trend underscores the material's potential to contribute to more sustainable automotive solutions within the Polypropylene Honeycomb Market.

Expansion in Construction Applications

The expansion of construction applications is a notable driver for the Polypropylene Honeycomb Market. As urbanization accelerates, the demand for lightweight and durable building materials is on the rise. Polypropylene honeycomb panels are increasingly used in wall partitions, ceilings, and flooring due to their excellent insulation properties and ease of installation. The construction sector is expected to witness a growth rate of around 4% annually, with polypropylene honeycomb products gaining traction for their cost-effectiveness and sustainability. This trend reflects a broader shift towards innovative building solutions, positioning the Polypropylene Honeycomb Market favorably for future growth.