Expansion of End-Use Industries

The expansion of various end-use industries, including automotive, electronics, and consumer goods, is a crucial driver for the Polyolefin and Engineering Plastic Compounding Market. As these sectors continue to grow, the demand for high-performance materials that offer durability, flexibility, and cost-effectiveness is increasing. For instance, the automotive industry is projected to see a rise in the use of engineering plastics for components such as dashboards and interior fittings, which are expected to enhance aesthetic appeal and functionality. This trend indicates a broader acceptance of polyolefins and engineering plastics across diverse applications, thereby propelling the Polyolefin and Engineering Plastic Compounding Market towards sustained growth.

Growth in Packaging Applications

The packaging sector is experiencing a notable transformation, significantly impacting the Polyolefin and Engineering Plastic Compounding Market. With the rise of e-commerce and the need for sustainable packaging solutions, polyolefins are increasingly utilized due to their versatility and cost-effectiveness. Reports indicate that the flexible packaging segment is expected to grow at a compound annual growth rate (CAGR) of approximately 4.5% over the next few years. This growth is driven by the material's ability to provide excellent barrier properties, which are essential for preserving product integrity. As consumer preferences shift towards convenience and sustainability, the demand for innovative packaging solutions will likely propel the Polyolefin and Engineering Plastic Compounding Market forward, fostering new opportunities for manufacturers.

Increasing Focus on Sustainability

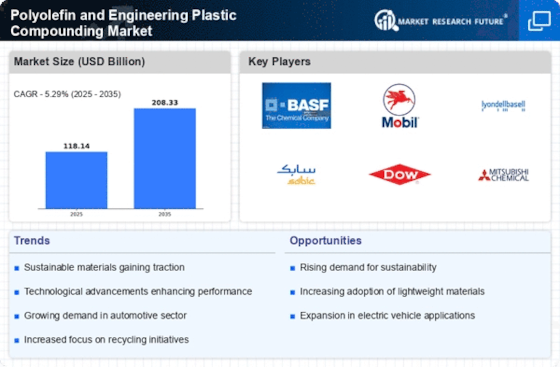

The growing emphasis on sustainability is reshaping the landscape of the Polyolefin and Engineering Plastic Compounding Market. Companies are increasingly adopting eco-friendly practices, including the use of recycled materials and the development of biodegradable options. This shift is partly driven by regulatory pressures and consumer demand for sustainable products. For instance, the market for biodegradable plastics is projected to expand significantly, with estimates suggesting a CAGR of around 10% in the coming years. As manufacturers strive to meet these sustainability goals, the Polyolefin and Engineering Plastic Compounding Market is likely to evolve, fostering innovation in material development and production processes that align with environmental considerations.

Rising Demand for Lightweight Materials

The increasing demand for lightweight materials across various industries is a pivotal driver for the Polyolefin and Engineering Plastic Compounding Market. As manufacturers seek to enhance fuel efficiency and reduce emissions, particularly in the automotive and aerospace sectors, polyolefins and engineering plastics are favored for their lightweight properties. For instance, the automotive industry is projected to witness a substantial shift towards these materials, with estimates suggesting that the use of lightweight components could lead to a reduction in vehicle weight by up to 20%. This trend not only supports environmental goals but also aligns with consumer preferences for more efficient vehicles. Consequently, the Polyolefin and Engineering Plastic Compounding Market is likely to experience robust growth as companies adapt to these evolving demands.

Technological Innovations in Compounding Processes

Technological advancements in compounding processes are significantly influencing the Polyolefin and Engineering Plastic Compounding Market. Innovations such as twin-screw extrusion and advanced mixing techniques enhance the efficiency and quality of compounded materials. These technologies enable manufacturers to produce customized compounds that meet specific performance criteria, thereby expanding application possibilities. For example, the introduction of smart compounding technologies allows for real-time monitoring and adjustments during production, leading to improved consistency and reduced waste. As industries increasingly demand high-performance materials, the Polyolefin and Engineering Plastic Compounding Market is poised for growth, driven by these technological enhancements that facilitate the development of superior products.