Rising Focus on Safety and Durability

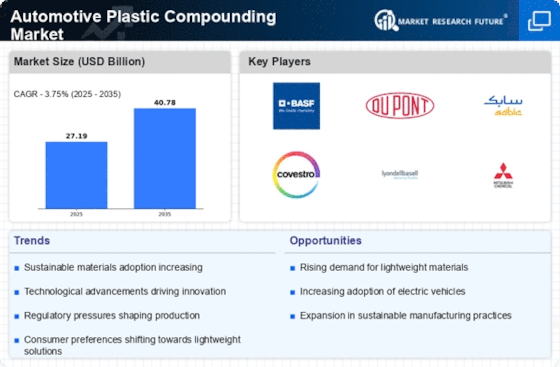

Safety and durability are paramount in the automotive sector, significantly influencing the Automotive Plastic Compounding Market. The increasing complexity of vehicle designs necessitates materials that can withstand rigorous conditions while ensuring passenger safety. Advanced plastic compounds are engineered to provide superior impact resistance and longevity, making them ideal for critical components such as bumpers and dashboards. Market data indicates that the demand for high-performance plastics is expected to grow at a compound annual growth rate of 5.2% over the next five years. This trend underscores the importance of safety and durability in shaping the Automotive Plastic Compounding Market.

Expansion of Electric Vehicle Production

The shift towards electric vehicles (EVs) is significantly impacting the Automotive Plastic Compounding Market. As automakers ramp up production of EVs, the demand for lightweight and efficient materials is intensifying. Plastic compounds play a crucial role in the design of EVs, contributing to weight reduction and improved battery efficiency. Recent projections suggest that the EV market will grow at a staggering rate, with electric vehicles expected to account for 30% of total vehicle sales by 2030. This transition presents a substantial opportunity for the Automotive Plastic Compounding Market, as manufacturers seek innovative solutions to meet the unique requirements of electric vehicle production.

Increasing Demand for Lightweight Materials

The Automotive Plastic Compounding Market is experiencing a notable surge in demand for lightweight materials. This trend is primarily driven by the automotive sector's ongoing efforts to enhance fuel efficiency and reduce emissions. As manufacturers strive to meet stringent regulatory standards, the adoption of lightweight plastics has become essential. According to recent data, the use of plastic components in vehicles can lead to weight reductions of up to 30% compared to traditional materials. This reduction not only improves fuel economy but also enhances vehicle performance. Consequently, the Automotive Plastic Compounding Market is poised for growth as automakers increasingly incorporate advanced plastic compounds into their designs.

Technological Innovations in Material Science

Technological advancements in material science are revolutionizing the Automotive Plastic Compounding Market. Innovations such as the development of bio-based plastics and enhanced polymer blends are expanding the range of applications for automotive components. These advancements not only improve the performance characteristics of plastics but also align with sustainability goals. For instance, the introduction of thermoplastic elastomers has enabled manufacturers to create flexible yet durable parts that can withstand extreme temperatures. As a result, the Automotive Plastic Compounding Market is likely to benefit from these innovations, which are expected to drive growth and diversification in product offerings.

Regulatory Compliance and Environmental Standards

Regulatory compliance and environmental standards are increasingly shaping the Automotive Plastic Compounding Market. Governments worldwide are implementing stringent regulations aimed at reducing vehicle emissions and promoting sustainable practices. As a result, automotive manufacturers are compelled to adopt eco-friendly materials and processes. The demand for recyclable and biodegradable plastics is on the rise, as companies strive to meet these regulatory requirements. Market analysis indicates that the eco-friendly segment of the Automotive Plastic Compounding Market is projected to grow by 6.5% annually. This trend highlights the critical role of regulatory compliance in driving innovation and sustainability within the automotive sector.