Growth in Consumer Electronics

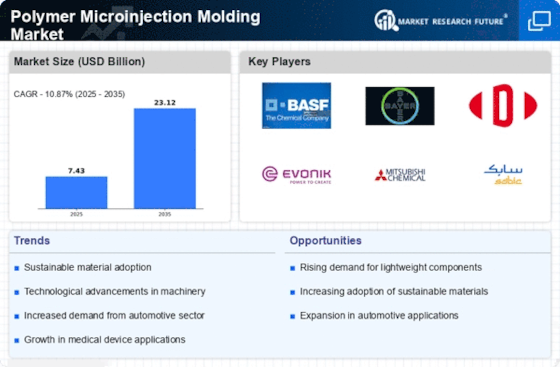

The Polymer Microinjection Molding Market is witnessing growth driven by the consumer electronics sector. With the continuous evolution of technology, there is a pressing need for smaller, more efficient components that can be produced with high precision. Microinjection molding allows manufacturers to create intricate designs that are essential for modern electronic devices, such as smartphones and wearables. The market for consumer electronics is projected to grow at a compound annual growth rate of over 5%, which suggests a corresponding increase in demand for polymer microinjection molded components. This trend indicates a robust future for the Polymer Microinjection Molding Market.

Customization and Design Flexibility

Customization and design flexibility are becoming increasingly important in the Polymer Microinjection Molding Market. As industries seek to differentiate their products, the ability to produce tailored components with unique specifications is crucial. Microinjection molding offers the advantage of creating complex geometries and intricate designs that traditional molding methods may not achieve. This flexibility allows manufacturers to respond swiftly to market demands and consumer preferences, thereby enhancing their competitive edge. The growing emphasis on personalized products across various sectors, including automotive and consumer goods, is likely to drive further growth in the Polymer Microinjection Molding Market.

Rising Demand for Lightweight Materials

The Polymer Microinjection Molding Market is experiencing a notable increase in demand for lightweight materials across various sectors, including automotive and consumer electronics. As manufacturers seek to enhance fuel efficiency and reduce energy consumption, lightweight polymers are becoming increasingly essential. This trend is particularly evident in the automotive sector, where the use of lightweight components can lead to a reduction in vehicle weight by up to 20%. Consequently, the Polymer Microinjection Molding Market is poised to benefit from this shift, as microinjection molding techniques allow for the precise production of complex, lightweight parts that meet stringent performance standards.

Regulatory Compliance and Quality Standards

The Polymer Microinjection Molding Market is increasingly shaped by stringent regulatory compliance and quality standards, particularly in sectors such as healthcare and automotive. Manufacturers are required to adhere to rigorous guidelines to ensure product safety and reliability. This necessity drives the demand for high-quality microinjection molded components that meet these standards. As regulations evolve, companies are investing in advanced technologies and processes to ensure compliance, which in turn fuels growth in the Polymer Microinjection Molding Market. The focus on quality assurance and regulatory adherence is likely to remain a key driver in the coming years.

Advancements in Medical Device Manufacturing

The Polymer Microinjection Molding Market is significantly influenced by advancements in medical device manufacturing. The healthcare sector is increasingly adopting microinjection molding techniques to produce intricate components for devices such as syringes, catheters, and diagnostic equipment. The ability to create highly precise and sterile components is paramount in this industry, and microinjection molding offers a viable solution. As the demand for innovative medical devices continues to rise, the Polymer Microinjection Molding Market is likely to expand, driven by the need for high-quality, reliable components that can be produced efficiently and at scale.