Research Methodology on Blow Molding Plastics Market

1. Introduction:-

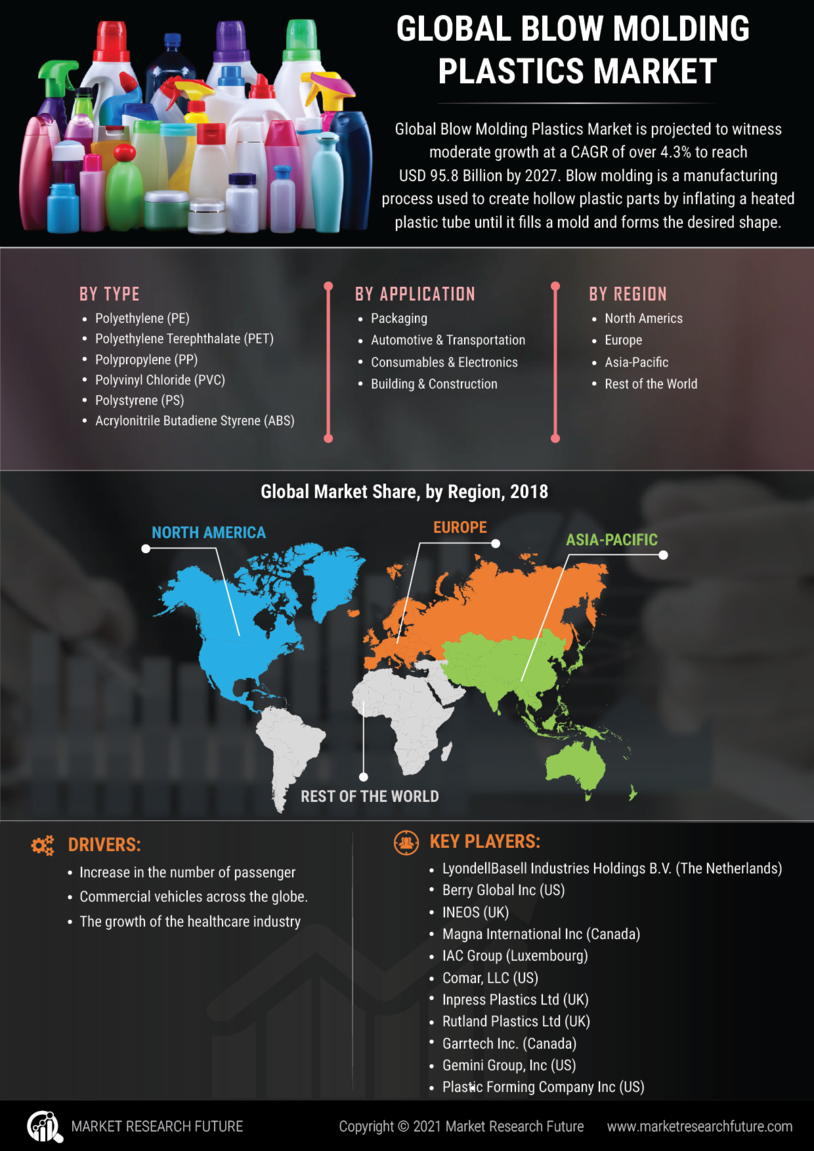

The research report aims to provide an in-depth understanding and analysis of the Blow Molding Plastics Market. It studies all aspects of the market including market trends, growth opportunities, and competitiveness. The report covers market size, market dynamics, technological development, competitive landscape, regional outlook, and recent trends in the Blow Molding Plastics market. It also contains in-depth information on the competitive landscape, industry players, and competitive environment. It further highlights the competitive strategies, synergies among industry players, and opportunities foreseen in the long-term perspective.

2. Research Methodology:-

2.1 Research Approach

The research methodology used for the report is based on qualitative and quantitative research strategies. Primary market research techniques are used to gather data from industry experts and key opinion leaders in the Blow Molding Plastics industry. Relevant industry sources were also consulted to gain insights into the Blow Moulding Plastics market. Historical data, figures, and market information sourced from different sources were referenced in the market analysis part of the report.

Secondary sources used to gain a further understanding of the Blow Molding Plastics market included media, journals, documentaries, and company websites. Secondary data gathered from sources relied upon in the report was collated, analyzed and cross-referenced to gain insights into the development, growth and trends in the Blow Moulding Plastics market. A market-leading research framework was also applied to analyze the information gathered on the Blow Moulding Plastics market.

2.2 Market Scope

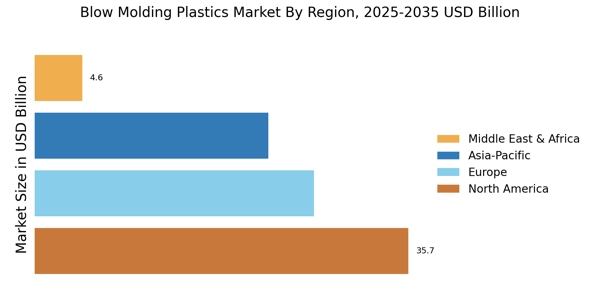

The research report on the Blow Moulding Plastics Market covers all segments of the Blow Moulding Plastics market. The report provides a detailed analysis of market performance, market trends, market drivers, restraints, emerging trends, wallet share analysis, market forecasts from 2023 to 2030, production capacity, pricing strategies, competitive landscape, and estimated market size in terms of value and volume. The report also explores the competitive strategies adopted by the players operating in the Blow Moulding Plastics market.

2.3 Base Year

The report covers the market development starting from 2023 to 2030. The Blow Molding Plastics market is tracked and studied over this period.

2.4 Sample Frame

The sample frame consisted of regional markets, market segments and width/depth of research covering the Blow Moulding Plastics market. The sample size includes all respondents from each region, market segment and width/depth of research, ensuring that the research is data-rich and comprehensive.

2.5 Sources of Information

Primary sources of information for this study include opinion leaders, industry experts and key opinion makers in the Blow Moulding Plastics industry. The secondary sources include directories and databases such as Bloomberg, Factiva, Frost & Sullivan, GlobalData, and Plastics News.

2.6 Data Collection

The research team made use of both primary and secondary sources to collect data for the Blow Moulding Plastics Market report. Primary data collection is done through in-depth interviews with key opinion makers and industry experts in the Blow Molding Plastics market. Secondary data collection was done through various sources such as financial statements, trade journals, and other publicly available documents.

2.7 Data Analysis

Data analysis is done with the help of top-down and bottom-up approaches to study, understand and analyze the market information gathered through interviews and documents. The primary data is collated, analyzed and cross-referenced with the secondary data to gain a better understanding of the market. Data is analyzed using various tools such as Porter’s Five Forces Analysis and industry segmentation tools to gain insights into the Blow Molding Plastics market.

2.8 Data Validation

The data obtained from the primary and secondary sources is validated through different levels and processes. Validation approaches include triangulation, comparison of similar markets, market segment interpolation, regression, and other procedures. The research team made use of both, quantitative as well as qualitative validation techniques to ensure the accuracy and reliability of data.

3. Conclusion

The research report on the Blow Molding Plastics Market provides an in-depth analysis of market segmentation, dynamics, and growth prospects. The research report uses market intelligence techniques such as Porter’s Five Forces Analysis, industry segmentation methods, and data triangulation to understand and analyze the market. The report also covers regional trends, competitive landscape, and market forecasts in terms of value and volumes. The research report leverages both primary and secondary sources of information to understand and analyze the market. All sources of data were cross-referenced and validated through multiple validation procedures. The goal of the report is to provide an accurate, detailed and insightful assessment of the Blow Moulding Plastics market.