Diverse End-User Industries

The Polyethylene Cast Film Market benefits from its diverse applications across various end-user industries. Sectors such as food and beverage, pharmaceuticals, and consumer goods are increasingly utilizing polyethylene cast films for their packaging needs. The food and beverage industry, in particular, is projected to account for a significant share of the market, driven by the need for hygienic and durable packaging solutions. This diversity in applications not only stabilizes demand but also encourages innovation within the Polyethylene Cast Film Market, as manufacturers strive to meet the specific requirements of different sectors.

Rising Demand for Flexible Packaging

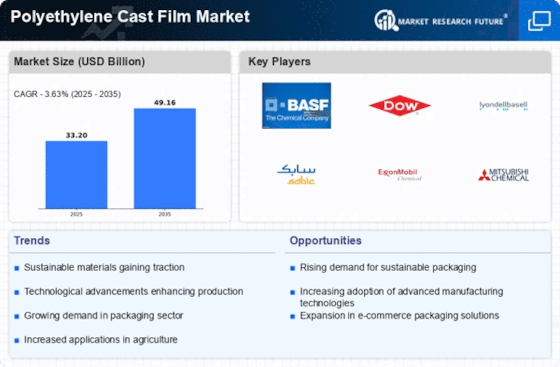

The increasing demand for flexible packaging solutions is a primary driver for the Polyethylene Cast Film Market. As consumer preferences shift towards lightweight and convenient packaging options, manufacturers are adapting their production strategies to meet these needs. The flexible packaging segment is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years. This growth is largely attributed to the food and beverage sector, which seeks to enhance product shelf life while minimizing waste. Consequently, the Polyethylene Cast Film Market is likely to experience heightened activity as companies innovate to provide sustainable and efficient packaging solutions.

Growth in E-commerce and Retail Sectors

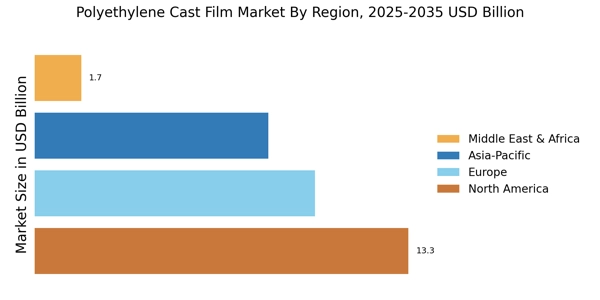

The expansion of e-commerce and retail sectors significantly influences the Polyethylene Cast Film Market. With the rise of online shopping, there is an increasing need for protective packaging that ensures product safety during transit. The e-commerce sector is expected to witness a growth rate of around 15% annually, which directly correlates with the demand for polyethylene cast films. Retailers are increasingly utilizing these films for their lightweight and durable properties, which help in reducing shipping costs and improving customer satisfaction. This trend suggests that the Polyethylene Cast Film Market will continue to thrive as businesses seek efficient packaging solutions.

Innovations in Film Production Technology

Technological advancements in film production are reshaping the Polyethylene Cast Film Market. Innovations such as improved extrusion techniques and enhanced polymer formulations are enabling manufacturers to produce films with superior properties, including increased strength and barrier performance. These advancements not only enhance product quality but also reduce production costs, making polyethylene cast films more competitive in various applications. The market is witnessing a shift towards high-performance films that cater to specific industry needs, indicating a robust growth trajectory for the Polyethylene Cast Film Market as technology continues to evolve.

Regulatory Support for Sustainable Materials

Regulatory frameworks promoting the use of sustainable materials are driving change within the Polyethylene Cast Film Market. Governments are increasingly implementing policies that encourage the adoption of eco-friendly packaging solutions, which is likely to boost demand for biodegradable and recyclable polyethylene films. This regulatory support aligns with the global push towards sustainability, compelling manufacturers to innovate and adapt their product offerings. As a result, the Polyethylene Cast Film Market is expected to see a shift towards more environmentally responsible practices, potentially leading to new market opportunities and growth.