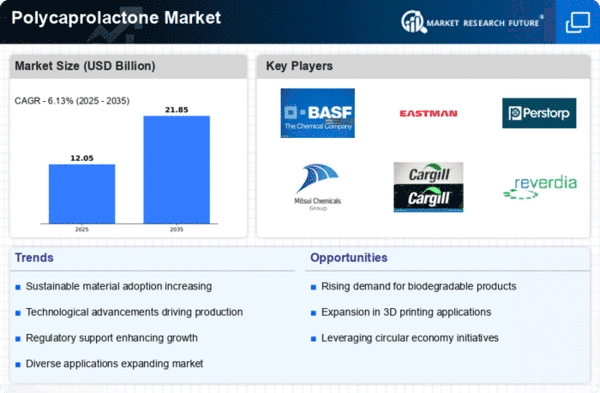

Market Growth Projections

The Global Polycaprolactone Market Industry is poised for substantial growth, with projections indicating a market value of 132.3 USD Billion in 2024 and an anticipated increase to 596.6 USD Billion by 2035. This remarkable growth trajectory suggests a compound annual growth rate of 14.68% from 2025 to 2035, reflecting the increasing adoption of polycaprolactone across various sectors. The market's expansion is driven by factors such as rising demand for biodegradable plastics, advancements in medical applications, and the integration of polycaprolactone in innovative manufacturing processes.

Growth in 3D Printing Technologies

The rise of 3D printing technologies is significantly influencing the Global Polycaprolactone Market Industry. Polycaprolactone Market's favorable properties, such as low melting point and excellent flow characteristics, make it an ideal material for 3D printing applications. Industries ranging from automotive to consumer goods are increasingly adopting 3D printing for prototyping and production, which in turn drives the demand for polycaprolactone. As this technology continues to advance, the market is expected to witness a compound annual growth rate of 14.68% from 2025 to 2035, reflecting the growing integration of polycaprolactone in innovative manufacturing processes.

Advancements in Medical Applications

The Global Polycaprolactone Market Industry is experiencing substantial growth due to advancements in medical applications. Polycaprolactone Market is increasingly utilized in drug delivery systems, tissue engineering, and sutures, owing to its biocompatibility and biodegradability. The material's ability to support cell growth and its favorable degradation rate make it a prime candidate for innovative medical solutions. As the healthcare sector continues to evolve, the demand for polycaprolactone in medical devices is likely to surge, contributing to the market's expansion. This growth aligns with the projected increase in market value, potentially reaching 596.6 USD Billion by 2035.

Increasing Use in Packaging Solutions

The Global Polycaprolactone Market Industry is benefiting from the increasing use of polycaprolactone in packaging solutions. As companies strive to reduce their environmental footprint, polycaprolactone's biodegradable properties make it an attractive option for packaging materials. This shift towards sustainable packaging is evident in various sectors, including food and consumer goods, where polycaprolactone is being utilized to create eco-friendly packaging alternatives. The growing consumer preference for sustainable products is likely to propel the market forward, contributing to the overall growth trajectory of the industry in the coming years.

Rising Demand in Biodegradable Plastics

The increasing global emphasis on sustainability drives the demand for biodegradable plastics, including polycaprolactone. As environmental concerns escalate, industries are seeking alternatives to conventional plastics. The Global Polycaprolactone Market Industry is witnessing a shift towards eco-friendly materials, with polycaprolactone being favored for its biodegradability and versatility. This trend is expected to contribute significantly to the market's growth, as consumers and manufacturers alike prioritize sustainable practices. The market is projected to reach 132.3 USD Billion in 2024, indicating a robust demand for biodegradable solutions in various applications.

Regulatory Support for Sustainable Materials

Regulatory frameworks promoting the use of sustainable materials are playing a crucial role in the Global Polycaprolactone Market Industry. Governments worldwide are implementing policies that encourage the adoption of biodegradable plastics, including polycaprolactone, to combat plastic pollution. This regulatory support is fostering innovation and investment in the development of sustainable materials, thereby enhancing the market's growth potential. As regulations become more stringent, industries are likely to pivot towards polycaprolactone, further solidifying its position in the market and contributing to its projected growth.