Market Analysis

In-depth Analysis of Polycaprolactone Market Industry Landscape

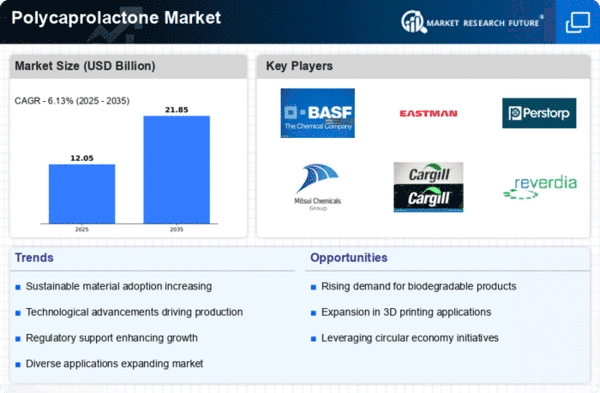

The Polycaprolactone (PCL) market is experiencing drastic changes due to multiple factors that affect its supply and demand. PCL is among the most widely used biodegradable polyesters in various sectors, including packaging, biomedical, and automotive industries. The trends in this sector are influenced by macroeconomic issues as well as technological advancements and environmental policies. One important factor pushing the PCL market forward is the growing need for sustainable, eco-friendly materials. As people globally start becoming environmentally conscious, many industries shift towards more organic alternatives than normal plastics. The biodegradability nature of PCL, along with its source from renewable sources, has made it gain popularity over time. In this case, packaging firms are responding to customer needs for greener activities, leading them to buy environmentally friendly products as per consumer preferences while meeting regulatory standards. Technological trends highly influence PCL market dynamics. Innovations in PCL products through research and development efforts make them better performing and expand their application areas as a whole. It is this dynamic innovation landscape that draws new participants into the market while also fostering competition between those who were there before. Global economic trends also affect PCL market dynamics. For example, the rising economies in emerging markets, especially Asia-Pacific, have increased demand for many products, including ones with PCL inputs. The increase in end-user sectors such as health care, packaging, and textiles in these regions has contributed significantly to the overall demand for PCL. Market players are, therefore, strategically expanding their footprints into these emerging markets to take advantage of the prevailing opportunities emanating from economic growth. Nonetheless, the PCL's market dynamics come with several challenges within them. Raw material price volatility, such as caprolactone, which is important to PCL production, greatly affects producers' overall cost structures. As a result of fluctuations in the prices of raw materials, planning and taking risks have often been necessary for profitability purposes. The medical healthcare industry is one of the significant contributors to polycaprolactone (PCL) market dynamics. The use of polycaprolactone (PCL) is continuously increasing in biomedical applications such as tissue engineering and drug delivery systems. Thereby, making it an attractive medical material due to its biocompatibility and biodegradability. As such, the demand for PCL in healthcare will continue to increase due to advancements within medical studies, thus shaping market dynamics.

Leave a Comment