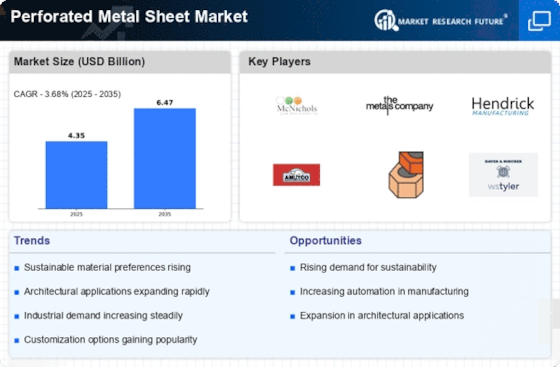

Rising Construction Activities

The resurgence of construction activities across various sectors appears to be a primary driver for the Perforated Metal Sheet Market. As urbanization accelerates, the demand for innovative building materials has surged. Perforated metal sheets are increasingly utilized in architectural designs, facades, and interior applications due to their aesthetic appeal and functional benefits. According to recent data, the construction sector is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. This growth is likely to bolster the demand for perforated metal sheets, as they offer versatility in design and are lightweight yet durable. Furthermore, the trend towards sustainable building practices may enhance the appeal of perforated metal sheets, as they can contribute to energy efficiency and resource conservation in construction projects.

Growing Focus on Aesthetic Design

The emphasis on aesthetic design in architecture and interior design is significantly influencing the Perforated Metal Sheet Market. Designers and architects are increasingly incorporating perforated metal sheets into their projects to achieve unique visual effects while maintaining functionality. The ability to customize patterns and hole sizes allows for creative expression, making these sheets a popular choice in modern design. Recent trends suggest that the architectural segment is poised for growth, with an increasing number of projects utilizing perforated metal for facades, ceilings, and decorative elements. This trend is likely to be supported by the rising consumer preference for visually appealing environments, which could further drive the demand for perforated metal sheets. As the market evolves, the intersection of functionality and aesthetics will continue to shape the landscape of the perforated metal sheet industry.

Technological Innovations in Manufacturing

Technological advancements in the manufacturing processes of perforated metal sheets are playing a crucial role in shaping the Perforated Metal Sheet Market. Innovations such as laser cutting and advanced punching techniques have enhanced the precision and efficiency of production. These technologies enable manufacturers to create intricate designs and patterns that meet the specific needs of various applications. Furthermore, the integration of automation in production lines is likely to reduce costs and improve turnaround times, making perforated metal sheets more accessible to a broader range of industries. Market analysis indicates that companies investing in these technologies are likely to gain a competitive edge, as they can offer higher quality products at lower prices. As the industry continues to embrace these innovations, the overall market for perforated metal sheets is expected to expand.

Increased Demand in Industrial Applications

The Perforated Metal Sheet Market is experiencing heightened demand from various industrial applications, including filtration, soundproofing, and safety barriers. Industries such as automotive, aerospace, and manufacturing are increasingly adopting perforated metal sheets for their unique properties. For instance, in the automotive sector, these sheets are utilized for lightweight components that enhance fuel efficiency. Market data indicates that the industrial segment is expected to account for a substantial share of the overall market, driven by the need for high-performance materials. Additionally, the ability of perforated metal sheets to facilitate airflow and reduce noise pollution makes them an attractive option for manufacturers seeking to improve operational efficiency. As industries continue to evolve, the versatility of perforated metal sheets positions them as a preferred choice for various applications.

Sustainability and Environmental Considerations

The growing emphasis on sustainability and environmental considerations is increasingly influencing the Perforated Metal Sheet Market. As industries and consumers alike prioritize eco-friendly materials, perforated metal sheets are gaining traction due to their recyclability and potential for energy efficiency. Many manufacturers are adopting sustainable practices in their production processes, which not only reduces waste but also appeals to environmentally conscious consumers. Market data suggests that the demand for sustainable building materials is on the rise, with a significant portion of the construction sector seeking to incorporate eco-friendly options. This trend is likely to drive the adoption of perforated metal sheets, as they can contribute to green building certifications and initiatives. As sustainability becomes a central theme in various industries, the perforated metal sheet market is expected to benefit from this shift.