Advancements in Material Science

Innovations in material science are significantly influencing the Micro Injection Molding Machine Market. The development of new polymers and composites that are suitable for micro molding applications is expanding the range of products that can be manufactured. For example, advanced thermoplastics and bio-based materials are gaining traction due to their superior properties and environmental benefits. This evolution in materials not only enhances the performance of molded components but also aligns with sustainability goals, as manufacturers seek to reduce their carbon footprint. The introduction of these advanced materials is expected to contribute to a market growth rate of around 7% annually, as companies increasingly invest in technologies that support the use of innovative materials.

Growing Focus on Lightweight Products

The Micro Injection Molding Machine Market is witnessing a growing focus on lightweight products, particularly in the automotive and aerospace sectors. As manufacturers strive to enhance fuel efficiency and reduce emissions, the demand for lightweight components is becoming increasingly pronounced. Micro injection molding offers a viable solution for producing lightweight parts with complex geometries that traditional methods may not achieve. This trend is expected to drive market growth, with projections indicating a potential increase in demand for micro injection molding machines by approximately 9% in the coming years. The emphasis on lightweight materials aligns with broader industry goals of sustainability and efficiency.

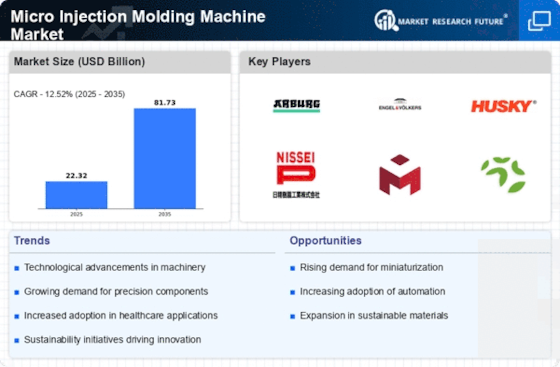

Rising Demand for Precision Components

The Micro Injection Molding Machine Market is experiencing a notable surge in demand for precision components across various sectors, including automotive, electronics, and medical devices. This trend is largely driven by the increasing need for intricate designs and high-quality finishes in manufactured products. For instance, the automotive sector is increasingly adopting micro-molded parts for lightweight and compact designs, which enhances fuel efficiency. According to industry estimates, the demand for precision components is projected to grow at a compound annual growth rate of approximately 8% over the next five years. This growth is indicative of the broader trend towards miniaturization in manufacturing, which is likely to further propel the micro injection molding machine market.

Expansion of Medical Device Manufacturing

The Micro Injection Molding Machine Market is significantly benefiting from the expansion of medical device manufacturing. The healthcare sector is increasingly relying on micro injection molding for the production of intricate components used in devices such as syringes, catheters, and diagnostic equipment. This method allows for high precision and the ability to produce small, complex parts that meet stringent regulatory standards. As the global demand for medical devices continues to rise, driven by an aging population and advancements in healthcare technology, the micro injection molding machine market is expected to experience robust growth. Market analysts predict an annual growth rate of around 8% in this segment, reflecting the critical role of micro molding in the future of medical manufacturing.

Increased Automation and Industry 4.0 Integration

The integration of automation and Industry 4.0 technologies is transforming the Micro Injection Molding Machine Market. Manufacturers are increasingly adopting smart technologies, such as IoT and AI, to enhance production efficiency and reduce operational costs. This shift towards automation allows for real-time monitoring and predictive maintenance, which can significantly minimize downtime. As a result, companies are likely to see improved productivity and reduced waste, which are critical factors in a competitive market. The automation trend is projected to drive the micro injection molding machine market, with an expected growth rate of 6% over the next few years, as businesses seek to optimize their manufacturing processes.