Growth in Biocompatible Materials

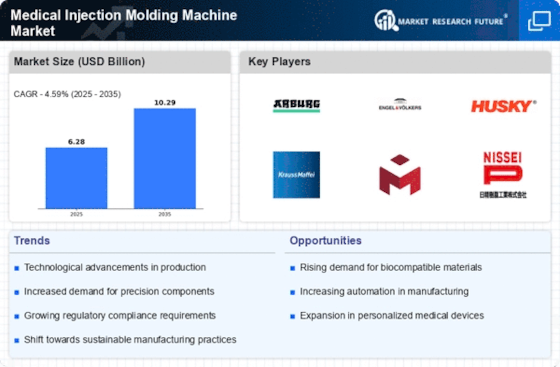

The expansion of biocompatible materials is significantly influencing the Medical Injection Molding Machine Market. As the healthcare sector increasingly adopts materials that are compatible with biological systems, the demand for specialized injection molding machines rises. These machines are designed to handle a variety of polymers that meet the necessary safety and performance criteria for medical applications. The market for biocompatible materials is expected to grow at a CAGR of 10% over the next five years, which will likely drive the need for advanced molding technologies capable of processing these materials effectively. This trend indicates a shift towards more innovative and adaptable manufacturing solutions.

Rising Demand for Medical Devices

The increasing demand for medical devices is a primary driver of the Medical Injection Molding Machine Market. As healthcare systems evolve, there is a notable rise in the production of devices such as syringes, catheters, and surgical instruments. This surge is attributed to an aging population and a growing emphasis on preventive healthcare. According to industry reports, the medical device market is projected to reach USD 500 billion by 2026, which directly influences the demand for efficient and precise injection molding machines. Manufacturers are thus compelled to invest in advanced molding technologies to meet the stringent quality standards and production volumes required in the medical sector.

Regulatory Compliance and Quality Standards

Regulatory compliance plays a crucial role in shaping the Medical Injection Molding Machine Market. Stringent regulations imposed by health authorities necessitate that medical devices meet high-quality standards. This has led to an increased focus on precision and reliability in the manufacturing process. Companies are investing in advanced injection molding technologies that ensure compliance with ISO and FDA standards. The need for traceability and documentation in the production process further drives the demand for sophisticated molding machines. As a result, manufacturers are likely to prioritize investments in equipment that not only meets regulatory requirements but also enhances production efficiency.

Technological Innovations in Molding Processes

Technological innovations are reshaping the Medical Injection Molding Machine Market. The introduction of automation, artificial intelligence, and advanced robotics in the molding process enhances efficiency and reduces production costs. These innovations allow for greater precision and faster cycle times, which are essential in the production of medical devices. As manufacturers seek to optimize their operations, the adoption of smart molding technologies is expected to increase. Reports suggest that the market for smart manufacturing in the medical sector could reach USD 100 billion by 2027, indicating a strong trend towards integrating advanced technologies in injection molding.

Increasing Investment in Healthcare Infrastructure

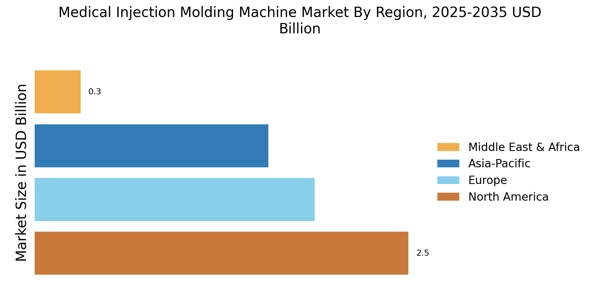

The increasing investment in healthcare infrastructure is a significant driver of the Medical Injection Molding Machine Market. Governments and private entities are allocating substantial resources to enhance healthcare facilities, which in turn boosts the demand for medical devices. This investment is particularly evident in emerging markets, where the establishment of new hospitals and clinics necessitates a reliable supply of medical equipment. As healthcare systems expand, the need for efficient manufacturing processes becomes paramount. Consequently, manufacturers are likely to invest in advanced injection molding machines to meet the growing demand for high-quality medical devices.