Technological Innovations

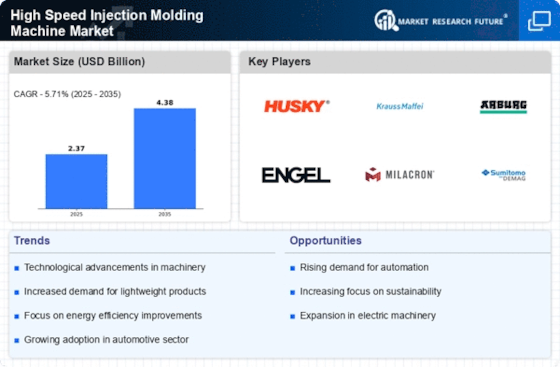

Technological innovations play a pivotal role in shaping the High Speed Injection Molding Machine Market. The introduction of advanced features such as automation, real-time monitoring, and enhanced precision has revolutionized the capabilities of injection molding machines. These innovations not only improve the quality of molded parts but also reduce waste and energy consumption. For instance, the integration of Industry 4.0 technologies allows for smarter manufacturing processes, enabling manufacturers to respond swiftly to market changes. As a result, the market for high-speed injection molding machines is projected to witness a compound annual growth rate of approximately 6% over the next few years, driven by the continuous evolution of technology in the sector.

Sustainability Initiatives

Sustainability initiatives are becoming increasingly prominent within the High Speed Injection Molding Machine Market. Manufacturers are under pressure to adopt environmentally friendly practices, leading to a rise in the use of recyclable materials and energy-efficient machines. High-speed injection molding technology allows for the production of parts with minimal waste, aligning with sustainability goals. Furthermore, the implementation of eco-friendly materials in the injection molding process is gaining traction, as companies seek to reduce their carbon footprint. Market data indicates that the demand for sustainable manufacturing solutions is expected to grow, with a projected increase in the adoption of high-speed injection molding machines that support these initiatives. This trend not only benefits the environment but also enhances brand reputation among increasingly eco-conscious consumers.

Increased Production Efficiency

The High Speed Injection Molding Machine Market is significantly influenced by the need for increased production efficiency across various manufacturing sectors. High-speed injection molding machines are designed to enhance cycle times, allowing manufacturers to produce more parts in less time. This efficiency is particularly crucial in industries such as packaging, where rapid production is essential to meet consumer demand. Recent statistics indicate that companies utilizing high-speed injection molding technology can achieve cycle time reductions of up to 30%, leading to substantial cost savings and improved profitability. As businesses strive to optimize their production processes, the adoption of high-speed injection molding machines is expected to grow, thereby driving the market's expansion.

Growing Consumer Electronics Sector

The High Speed Injection Molding Machine Market is significantly bolstered by the rapid growth of the consumer electronics sector. With the increasing demand for electronic devices such as smartphones, tablets, and wearables, manufacturers are turning to high-speed injection molding to produce intricate and high-quality components. This sector requires precision and speed, which high-speed injection molding machines can provide. Recent market analyses suggest that the consumer electronics industry is expected to grow at a rate of around 7% annually, further fueling the need for efficient and reliable injection molding solutions. As consumer preferences evolve, the high-speed injection molding market is likely to expand in tandem with the electronics sector.

Rising Demand for Lightweight Materials

The High Speed Injection Molding Machine Market is experiencing a notable increase in demand for lightweight materials, particularly in sectors such as automotive and consumer goods. Manufacturers are increasingly adopting high-speed injection molding techniques to produce components that are not only lightweight but also maintain structural integrity. This shift is driven by the need for improved fuel efficiency and performance in vehicles, as well as the growing consumer preference for lightweight products. According to recent data, the automotive sector alone is projected to account for a significant share of the high-speed injection molding market, with an expected growth rate of over 5% annually. As industries continue to prioritize lightweight solutions, the demand for high-speed injection molding machines is likely to rise, further propelling the market forward.