Growth in Aerospace and Defense

The aerospace and defense sectors are experiencing robust growth, which is likely to propel the Metal Finishing Chemical Market. With increasing investments in aircraft manufacturing and maintenance, the demand for high-performance metal finishing chemicals is expected to rise. These chemicals are essential for ensuring the longevity and safety of aircraft components, which must withstand extreme conditions. The aerospace industry is projected to grow at a rate of around 5% annually, leading to a heightened need for specialized coatings that offer protection against corrosion and wear. Additionally, the defense sector's focus on advanced materials and technologies may further stimulate demand for innovative metal finishing solutions. As a result, the aerospace and defense industries are poised to be significant contributors to the growth of the Metal Finishing Chemical Market.

Increasing Focus on Sustainability

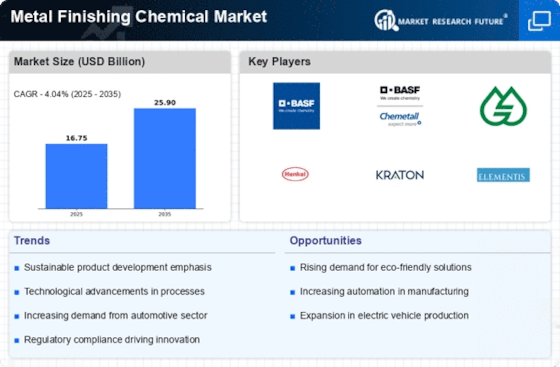

Sustainability is becoming a critical focus within the Metal Finishing Chemical Market, as companies strive to reduce their environmental footprint. The demand for eco-friendly metal finishing chemicals, such as water-based coatings and biodegradable solvents, is on the rise. Regulatory pressures and consumer preferences for sustainable products are driving manufacturers to adopt greener practices. The market for sustainable metal finishing solutions is projected to grow significantly, with estimates suggesting a potential increase of over 6% annually. This shift towards sustainability not only addresses environmental concerns but also opens new opportunities for innovation in chemical formulations. As a result, the emphasis on sustainable practices is likely to play a pivotal role in shaping the future of the Metal Finishing Chemical Market.

Rising Demand from Automotive Sector

The automotive sector is a primary driver for the Metal Finishing Chemical Market, as manufacturers increasingly seek to enhance the durability and aesthetic appeal of vehicles. The demand for high-performance coatings and finishes is expected to rise, with the automotive industry projected to grow at a compound annual growth rate of approximately 4.5% over the next few years. This growth is likely to spur the need for advanced metal finishing chemicals that provide corrosion resistance and improved surface quality. As electric vehicles gain traction, the requirement for specialized coatings that can withstand higher temperatures and provide better insulation is also anticipated to increase. Consequently, the automotive sector's expansion is expected to significantly influence the Metal Finishing Chemical Market, driving innovation and investment in new chemical formulations.

Technological Innovations in Coating Processes

Technological advancements in coating processes are transforming the Metal Finishing Chemical Market. Innovations such as electroplating, powder coating, and nanotechnology are enhancing the efficiency and effectiveness of metal finishing applications. These technologies not only improve the quality of finishes but also reduce waste and environmental impact, aligning with sustainability goals. The introduction of automated systems and robotics in coating applications is expected to streamline production processes, thereby increasing output and reducing costs. As manufacturers seek to adopt these advanced technologies, the demand for specialized metal finishing chemicals that complement these processes is likely to grow. This trend indicates a shift towards more efficient and environmentally friendly practices within the Metal Finishing Chemical Market.

Expansion of Electronics and Electrical Industries

The electronics and electrical industries are expanding rapidly, which is likely to have a profound impact on the Metal Finishing Chemical Market. As the demand for electronic devices continues to rise, the need for high-quality metal finishes that enhance conductivity and protect against corrosion is becoming increasingly important. The electronics sector is expected to grow at a rate of approximately 5% annually, driven by advancements in technology and consumer electronics. This growth is anticipated to create a substantial demand for specialized metal finishing chemicals that cater to the unique requirements of electronic components. Consequently, the expansion of the electronics and electrical industries is expected to be a key driver of growth within the Metal Finishing Chemical Market.