Regulatory Compliance

Regulatory compliance is a critical driver for the Metal Anodizing Market. As governments implement stricter regulations regarding environmental protection and product safety, manufacturers are compelled to adopt anodizing processes that meet these standards. Compliance with regulations not only ensures product quality but also enhances marketability. In 2025, the Metal Anodizing Market is expected to benefit from increased investments in compliant anodizing technologies. Companies that prioritize regulatory adherence are likely to gain a competitive edge, as consumers increasingly favor products that align with safety valve and environmental standards. This focus on compliance is anticipated to drive growth and innovation within the Metal Anodizing Market.

Sustainability Initiatives

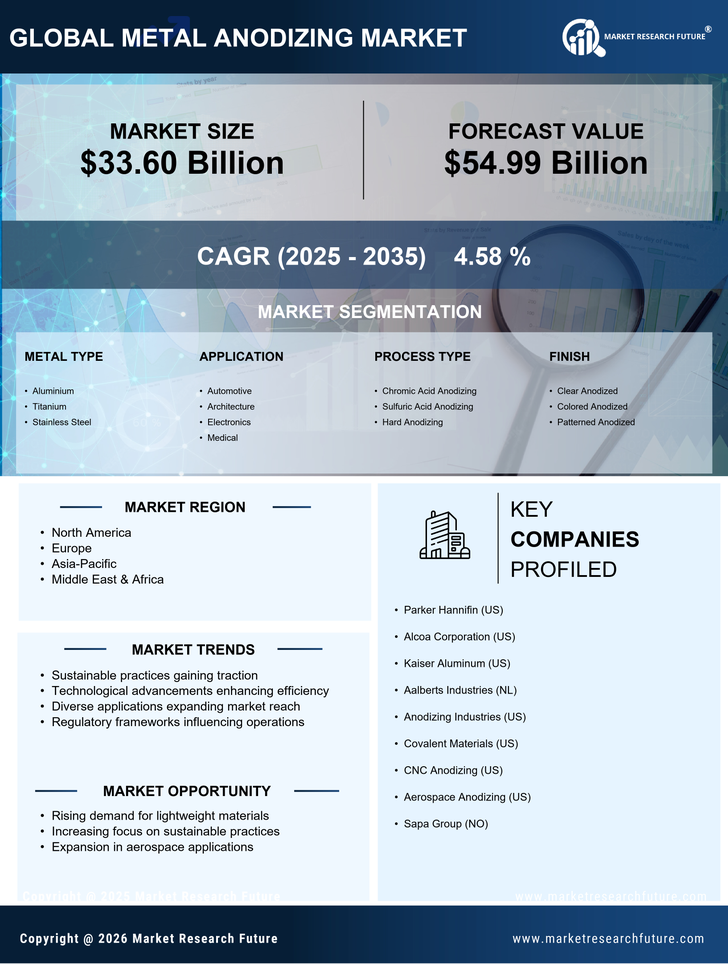

The Metal Anodizing Market is increasingly influenced by sustainability initiatives. As environmental concerns gain prominence, industries are seeking eco-friendly processes. Anodizing, being a non-toxic and energy-efficient method, aligns well with these initiatives. The demand for anodized products is projected to rise, as manufacturers aim to reduce their carbon footprint. In 2025, the market is expected to witness a growth rate of approximately 6% due to the increasing emphasis on sustainable practices. Companies are investing in advanced anodizing technologies that minimize waste and energy consumption, further driving the Metal Anodizing Market. This shift towards sustainability not only enhances the appeal of anodized products but also positions them favorably in a competitive market.

Technological Advancements

Technological advancements play a pivotal role in shaping the Metal Anodizing Market. Innovations in anodizing techniques, such as hard anodizing and colored anodizing, have expanded the application range of anodized products. The integration of automation and digital technologies in anodizing processes enhances efficiency and precision, leading to improved product quality. In 2025, the market is anticipated to grow as manufacturers adopt these advanced technologies to meet the evolving demands of various sectors, including aerospace and automotive. The ability to produce lightweight, durable, and aesthetically pleasing components through modern anodizing methods is likely to attract new customers, thereby propelling the Metal Anodizing Market forward.

Growing Demand in Diverse Industries

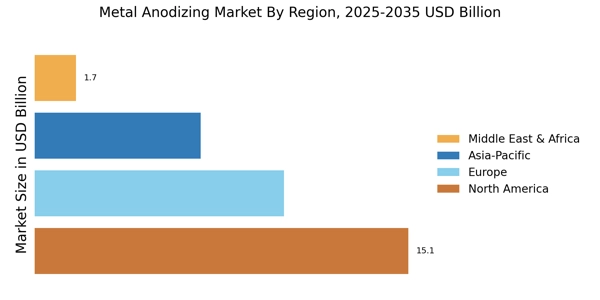

The Metal Anodizing Market is experiencing a surge in demand across various sectors. Industries such as automotive, aerospace, and electronics are increasingly utilizing anodized components for their superior corrosion resistance and aesthetic appeal. The automotive sector, in particular, is projected to account for a significant share of the market, driven by the need for lightweight materials that enhance fuel efficiency. In 2025, the demand for anodized aluminum in the aerospace industry is expected to rise, as manufacturers seek materials that can withstand extreme conditions. This growing demand across diverse industries is likely to bolster the Metal Anodizing Market, creating new opportunities for manufacturers and suppliers.

Rising Consumer Preferences for Aesthetic Appeal

Rising consumer preferences for aesthetic appeal significantly influence the Metal Anodizing Market. Anodized products are favored for their vibrant colors and finishes, making them highly sought after in sectors such as architecture and consumer goods. As consumers become more design-conscious, the demand for anodized aluminum in decorative applications is likely to increase. In 2025, the market is projected to expand as manufacturers respond to these aesthetic demands by offering a wider range of anodized finishes. This trend not only enhances the visual appeal of products but also contributes to the overall growth of the Metal Anodizing Market, as companies strive to meet the evolving tastes of consumers.