Growth in Chemical Processing

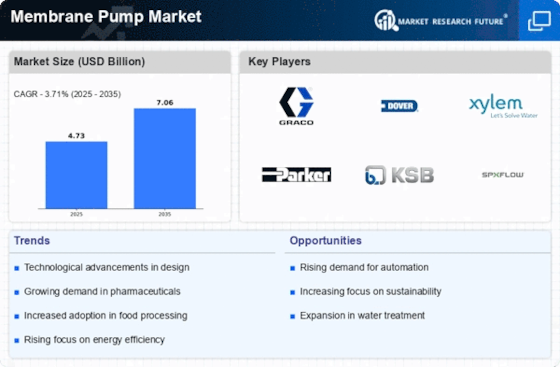

The Membrane Pump Market is significantly influenced by the expansion of the chemical processing sector. As industries strive for higher efficiency and safety standards, the demand for reliable pumping solutions has escalated. Membrane pumps are particularly favored for their ability to handle corrosive and viscous fluids, making them ideal for various chemical applications. Recent statistics indicate that the chemical processing industry is expected to witness a growth rate of around 5% annually, which could lead to increased adoption of membrane pumps. This trend suggests that manufacturers are likely to invest in innovative membrane pump technologies to meet the evolving needs of the chemical sector, thereby enhancing their market presence within the Membrane Pump Market.

Rising Demand in Water Treatment

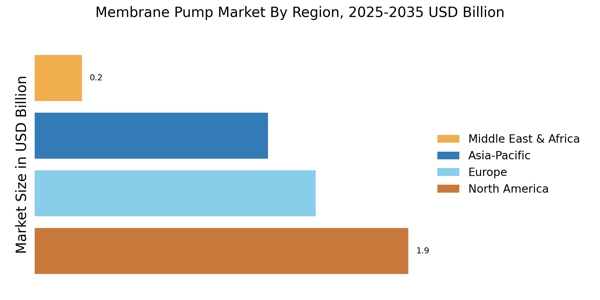

The Membrane Pump Market experiences a notable surge in demand due to the increasing need for efficient water treatment solutions. As urbanization accelerates, the pressure on water resources intensifies, prompting municipalities and industries to seek advanced pumping technologies. Membrane pumps, known for their precision and reliability, are becoming essential in various applications, including wastewater management and desalination processes. According to recent data, the water treatment sector is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This growth is likely to drive investments in membrane pump technologies, as they offer enhanced performance and lower operational costs, thereby solidifying their position in the Membrane Pump Market.

Increased Focus on Energy Efficiency

Energy efficiency has emerged as a critical driver in the Membrane Pump Market, as industries seek to reduce operational costs and environmental impact. Membrane pumps are recognized for their energy-saving capabilities, which can lead to substantial cost reductions over time. With energy prices fluctuating, companies are increasingly prioritizing technologies that offer lower energy consumption without compromising performance. Reports indicate that energy-efficient pumping solutions can reduce energy costs by up to 30%, making membrane pumps an attractive option for various applications. This growing emphasis on sustainability and efficiency is likely to propel the adoption of membrane pumps, further solidifying their role in the Membrane Pump Market.

Regulatory Compliance and Safety Standards

The Membrane Pump Market is also shaped by stringent regulatory compliance and safety standards across various sectors. Industries such as pharmaceuticals, food and beverage, and chemicals are subject to rigorous regulations that mandate the use of safe and reliable pumping solutions. Membrane pumps, with their ability to minimize contamination risks and ensure precise fluid handling, are increasingly being adopted to meet these standards. As regulatory bodies continue to enforce stricter guidelines, the demand for compliant pumping technologies is expected to rise. This trend indicates that manufacturers in the Membrane Pump Market may need to innovate continuously to align with evolving regulations, thereby enhancing their competitive edge.

Technological Innovations and Product Development

Technological innovations play a pivotal role in shaping the Membrane Pump Market. Continuous advancements in materials and design are leading to the development of more efficient and durable membrane pumps. Innovations such as smart pumping systems, which integrate IoT technology for real-time monitoring and control, are gaining traction. These advancements not only improve operational efficiency but also enhance the overall user experience. Market data suggests that the introduction of new technologies could potentially increase the market share of membrane pumps by attracting a broader range of applications. As industries seek to leverage these innovations, the Membrane Pump Market is likely to witness a dynamic shift towards more sophisticated pumping solutions.