Diverse Applications of Mechanical Diaphragm Pump Market

The versatility of mechanical diaphragm pumps is a significant driver in the Mechanical Diaphragm Pump Market. These pumps are utilized across various sectors, including pharmaceuticals, food and beverage, and water treatment, due to their ability to handle a wide range of fluids, including corrosive and viscous materials. The pharmaceutical industry, in particular, is projected to expand, with an estimated growth rate of 6.5% in the coming years, thereby increasing the demand for reliable pumping solutions. Additionally, the food and beverage sector's focus on hygiene and safety standards further boosts the need for diaphragm pumps that ensure contamination-free operations. This diverse applicability not only enhances market resilience but also opens new avenues for innovation and growth within the Mechanical Diaphragm Pump Market.

Regulatory Compliance in Mechanical Diaphragm Pump Market

Regulatory compliance is a critical factor influencing the Mechanical Diaphragm Pump Market. As industries face stringent regulations regarding safety and environmental impact, the demand for pumps that meet these standards is on the rise. Mechanical diaphragm pumps are often preferred for their ability to operate safely under high pressures and their compliance with various industry standards, such as ISO and API. The increasing emphasis on compliance is expected to drive market growth, with a projected increase in demand for certified pumping solutions. Furthermore, industries such as oil and gas, which are heavily regulated, are likely to invest in advanced diaphragm pumps to ensure adherence to safety protocols. This regulatory landscape is shaping the Mechanical Diaphragm Pump Market, pushing manufacturers to innovate and enhance their product offerings.

Sustainability Initiatives in Mechanical Diaphragm Pump Market

Sustainability initiatives are becoming a pivotal driver in the Mechanical Diaphragm Pump Market. As environmental regulations tighten, industries are compelled to adopt eco-friendly practices, including the use of energy-efficient pumps. Mechanical diaphragm pumps, known for their ability to handle hazardous materials without leakage, are increasingly favored in sectors such as chemical processing and wastewater management. The market is witnessing a shift towards pumps that minimize energy consumption and reduce carbon footprints. According to recent data, the demand for sustainable pumping solutions is expected to increase by 7% annually, reflecting a broader trend towards sustainability in industrial operations. This focus on environmental responsibility is likely to propel the Mechanical Diaphragm Pump Market forward, as companies seek to align with global sustainability goals.

Technological Advancements in Mechanical Diaphragm Pump Market

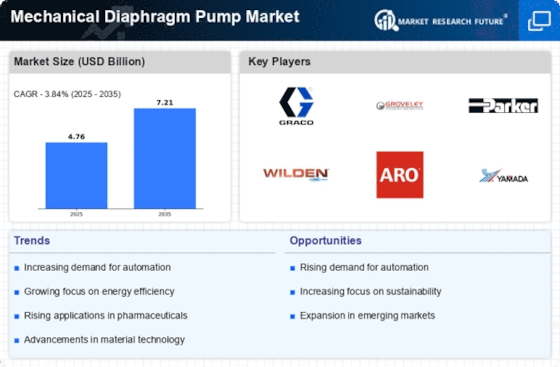

The Mechanical Diaphragm Pump Market is experiencing a surge in technological advancements that enhance pump efficiency and reliability. Innovations such as smart monitoring systems and advanced materials are being integrated into pump designs, which not only improve performance but also extend the lifespan of the equipment. For instance, the introduction of IoT-enabled pumps allows for real-time data collection and predictive maintenance, reducing downtime and operational costs. Furthermore, the market is projected to grow at a compound annual growth rate of approximately 5.2% over the next few years, driven by these technological improvements. As industries increasingly adopt automation and digital solutions, the demand for advanced diaphragm pumps is likely to rise, positioning the Mechanical Diaphragm Pump Market for substantial growth.

Rising Demand in Emerging Markets for Mechanical Diaphragm Pump Market

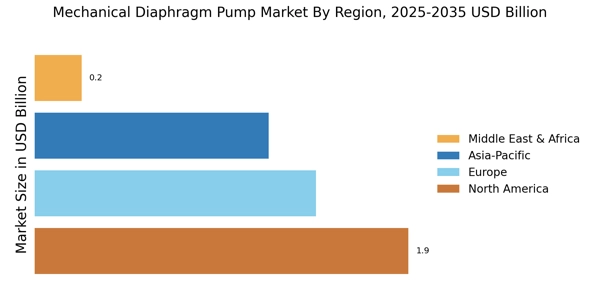

Emerging markets are witnessing a rising demand for mechanical diaphragm pumps, significantly impacting the Mechanical Diaphragm Pump Market. As industrialization accelerates in regions such as Asia-Pacific and Latin America, the need for efficient and reliable pumping solutions is becoming increasingly apparent. The growth of sectors such as construction, mining, and agriculture in these regions is driving the demand for diaphragm pumps that can handle various applications, from fluid transfer to chemical dosing. Market analysts project that the demand in these emerging economies could grow by approximately 8% annually, reflecting the rapid expansion of industrial activities. This trend presents a substantial opportunity for manufacturers to expand their reach and cater to the unique needs of these markets, thereby shaping the future of the Mechanical Diaphragm Pump Market.