Technological Advancements

Technological innovations play a pivotal role in shaping the Global Air Operated Double Diaphragm Pumps Market Industry. Recent advancements in materials and design have enhanced pump efficiency and durability, making them more appealing to end-users. For example, the introduction of lightweight composite materials has improved portability and ease of installation. Furthermore, the integration of smart technologies allows for real-time monitoring and predictive maintenance, reducing downtime. Such innovations are likely to drive market growth, as industries increasingly prioritize efficiency and reliability in their operations.

Expansion in Emerging Markets

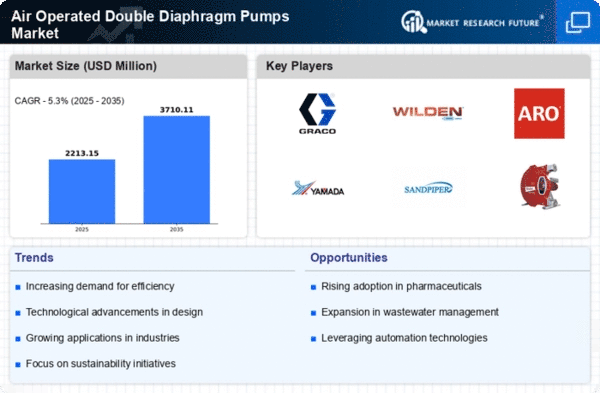

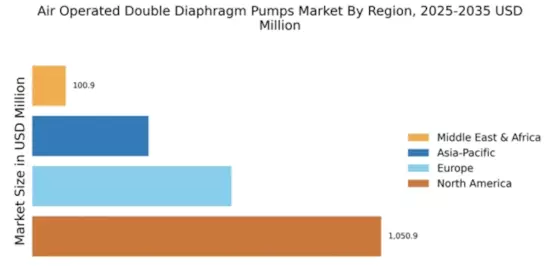

Emerging markets present significant growth opportunities for the Global Air Operated Double Diaphragm Pumps Market Industry. Rapid industrialization and urbanization in regions such as Asia-Pacific and Latin America are driving demand for efficient fluid handling solutions. As these economies expand, the need for reliable pumping systems in sectors like construction, mining, and agriculture is increasing. This trend is expected to contribute to the market's growth trajectory, with projections indicating a rise to 3.71 USD Billion by 2035, underscoring the potential of these markets.

Growing Focus on Sustainability

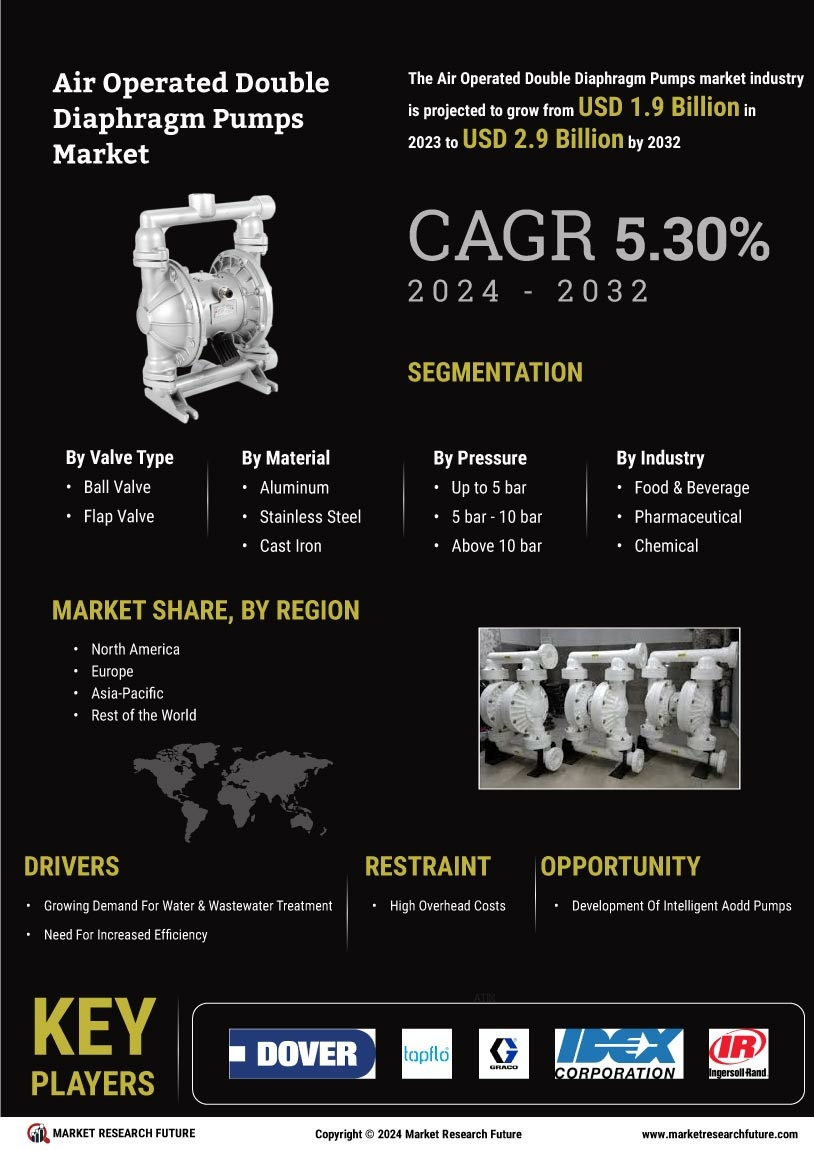

A growing emphasis on sustainability and eco-friendly practices is shaping the Global Air Operated Double Diaphragm Pumps Market Industry. Companies are increasingly seeking solutions that reduce environmental impact, leading to a preference for diaphragm pumps that minimize waste and energy consumption. The market is projected to grow at a CAGR of 5.3% from 2025 to 2035, reflecting the shift towards sustainable practices. This trend is particularly evident in the food and beverage sector, where companies are adopting greener technologies to meet consumer demand for sustainable products.

Increasing Demand in Various Industries

The Global Air Operated Double Diaphragm Pumps Market Industry experiences heightened demand across diverse sectors such as chemical processing, food and beverage, and pharmaceuticals. These pumps are favored for their ability to handle viscous fluids and slurries, which is crucial in industries requiring precise fluid transfer. For instance, the chemical sector's growth is projected to contribute significantly to the market, with the industry expected to reach 2.1 USD Billion in 2024. This trend indicates a robust adoption of diaphragm pumps, as industries seek reliable solutions for fluid management.

Regulatory Compliance and Safety Standards

The Global Air Operated Double Diaphragm Pumps Market Industry is influenced by stringent regulatory compliance and safety standards across various sectors. Industries are mandated to adhere to environmental regulations, which often necessitate the use of pumps that minimize leakage and emissions. This compliance drives the adoption of diaphragm pumps, known for their leak-free operation and ability to handle hazardous materials safely. As regulations become more stringent, the demand for reliable and compliant pumping solutions is expected to rise, further propelling market growth.