Customization Trends in Manufacturing

The Material Jetting Process 3D Printing Market is significantly influenced by the rising trend of customization in manufacturing. As consumers increasingly demand personalized products, manufacturers are turning to material jetting to meet these expectations. This process allows for the creation of bespoke items tailored to individual specifications, which is particularly advantageous in sectors like fashion, jewelry, and consumer goods. The ability to produce small batches of customized products without the need for extensive tooling is a key driver for the adoption of material jetting technologies. Market analysis suggests that the customization segment is likely to grow, with a projected increase in demand for personalized manufacturing solutions, further solidifying the role of material jetting in modern production.

Growing Demand for Prototyping Solutions

The Material Jetting Process 3D Printing Market is witnessing an increasing demand for rapid prototyping solutions across various sectors. Companies are seeking efficient ways to develop prototypes that can be tested and modified quickly, reducing time-to-market for new products. Material jetting offers the advantage of producing high-resolution prototypes with intricate details, which is essential for industries such as consumer electronics and automotive. According to recent statistics, the prototyping segment within the 3D printing market is expected to account for a substantial share, driven by the need for faster product development cycles. This trend indicates a robust growth trajectory for material jetting technologies as businesses prioritize innovation and speed.

Sustainability and Eco-Friendly Practices

The Material Jetting Process 3D Printing Market is increasingly aligning with sustainability initiatives as companies seek to reduce their environmental footprint. Material jetting processes can minimize waste by using only the necessary amount of material for production, which contrasts with traditional subtractive manufacturing methods. Furthermore, advancements in bio-based and recyclable materials are enhancing the sustainability profile of material jetting. As consumers and regulatory bodies place greater emphasis on eco-friendly practices, manufacturers are likely to adopt these technologies to comply with environmental standards. Recent reports indicate that the demand for sustainable manufacturing solutions is on the rise, suggesting a favorable outlook for material jetting processes that prioritize environmental responsibility.

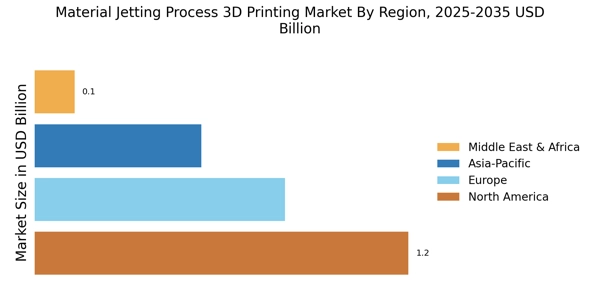

Expansion in Aerospace and Automotive Sectors

The Material Jetting Process 3D Printing Market is poised for growth due to its expanding applications in the aerospace and automotive sectors. These industries are increasingly utilizing material jetting for producing lightweight components that enhance fuel efficiency and performance. The ability to create complex geometries that traditional manufacturing methods cannot achieve is a significant advantage. Recent data indicates that the aerospace sector alone is expected to invest heavily in additive manufacturing technologies, including material jetting, to streamline production processes and reduce costs. This trend suggests a robust demand for material jetting solutions, as companies in these sectors seek innovative ways to improve their manufacturing capabilities.

Technological Advancements in Material Jetting

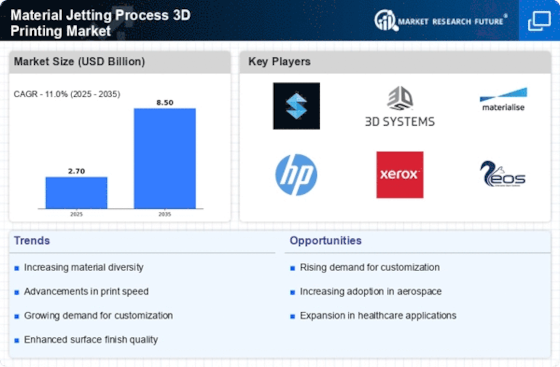

The Material Jetting Process 3D Printing Market is experiencing a surge in technological advancements that enhance printing capabilities. Innovations in print head technology and material formulations are enabling the production of more complex geometries and finer details. For instance, the introduction of multi-material printing allows for the creation of parts with varying properties, which is particularly beneficial in industries such as aerospace and automotive. As these technologies evolve, they are likely to attract more manufacturers to adopt material jetting processes, thereby expanding the market. Recent data indicates that the market for advanced 3D printing technologies is projected to grow at a compound annual growth rate of over 20% in the coming years, underscoring the potential of material jetting in various applications.