Increasing Regulatory Compliance

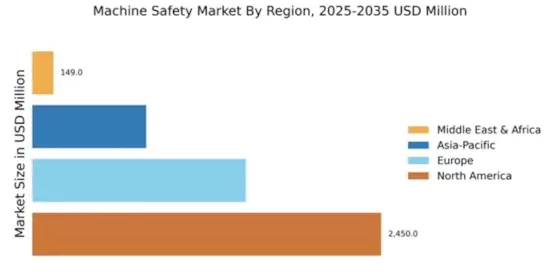

The Global Machine Safety Market Industry experiences a notable drive due to the increasing regulatory compliance requirements imposed by governments worldwide. Regulations such as the Machinery Directive in Europe and OSHA standards in the United States necessitate stringent safety measures in manufacturing processes. Companies are compelled to invest in safety systems and technologies to adhere to these regulations, thereby enhancing workplace safety. This trend is expected to contribute significantly to the market's growth, as organizations prioritize compliance to avoid penalties and ensure employee safety. As a result, the Global Machine Safety Market is projected to reach 4.9 USD Billion in 2024, reflecting the urgency of compliance.

Expansion of the Manufacturing Sector

The expansion of the manufacturing sector globally serves as a significant driver for the Global Machine Safety Market Industry. As countries invest in industrial growth and infrastructure development, the demand for machinery and equipment rises correspondingly. This expansion necessitates the implementation of effective safety measures to mitigate risks associated with increased machinery usage. Governments and industry bodies are advocating for enhanced safety standards, further fueling the demand for machine safety solutions. The growth trajectory of the manufacturing sector is expected to bolster the market, as organizations seek to ensure safety amidst rising production demands.

Growing Awareness of Workplace Safety

The growing awareness of workplace safety among employees and employers significantly influences the Global Machine Safety Market Industry. As incidents of workplace accidents and injuries garner media attention, organizations are becoming more proactive in implementing safety measures. Training programs and safety audits are increasingly prioritized to foster a culture of safety within organizations. This heightened awareness not only protects employees but also enhances productivity and reduces operational costs associated with accidents. Consequently, the demand for machine safety solutions is on the rise, further propelling the market's growth as companies seek to create safer work environments.

Rising Demand for Automation in Manufacturing

The rising demand for automation in manufacturing processes is a pivotal driver of the Global Machine Safety Market Industry. As industries strive for increased efficiency and productivity, the integration of automated systems becomes essential. However, automation introduces new safety challenges, necessitating the implementation of robust safety measures to protect workers and equipment. Companies are investing in safety technologies that can seamlessly integrate with automated systems, ensuring compliance with safety standards. This trend is likely to sustain the market's growth, as the automation wave continues to reshape the manufacturing landscape, compelling organizations to prioritize machine safety.

Technological Advancements in Safety Solutions

Technological advancements play a crucial role in shaping the Global Machine Safety Market Industry. Innovations such as advanced sensors, machine learning algorithms, and IoT integration are revolutionizing safety protocols in manufacturing environments. These technologies enable real-time monitoring and predictive maintenance, reducing the likelihood of accidents and enhancing operational efficiency. For instance, the implementation of smart safety systems allows for immediate responses to potential hazards, thereby minimizing risks. As organizations increasingly adopt these cutting-edge solutions, the market is anticipated to grow at a CAGR of 7.95% from 2025 to 2035, potentially reaching 11.4 USD Billion by 2035.