Growth of the E-commerce Sector

The expansion of the e-commerce sector is a significant driver for the Lithographic Printing Chemical Market. As online shopping continues to rise, the need for effective packaging and branding becomes increasingly important. Lithographic printing provides the high-quality graphics and vibrant colors that are essential for attracting consumers in a digital marketplace. In 2025, the e-commerce industry is expected to contribute to a 5% increase in the demand for lithographic printing chemicals, as companies invest in packaging that enhances their brand visibility. This trend underscores the importance of lithographic printing in creating a competitive edge in the e-commerce landscape.

Emerging Markets and Economic Growth

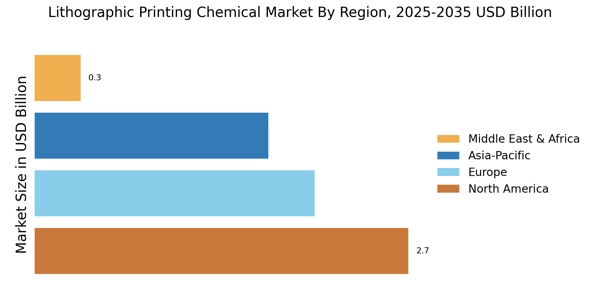

Emerging markets are playing a crucial role in the growth of the Lithographic Printing Chemical Market. As economies develop, there is an increasing demand for printed materials across various sectors, including advertising, packaging, and publishing. This growth is particularly evident in regions where urbanization and consumer spending are on the rise. In 2025, it is estimated that emerging markets will contribute to a 4% increase in the demand for lithographic printing chemicals, as businesses expand their operations and seek to capitalize on new opportunities. This trend suggests a promising outlook for the lithographic printing chemicals sector in these regions.

Rising Demand for Packaging Solutions

The increasing demand for packaging solutions across various sectors is a pivotal driver for the Lithographic Printing Chemical Market. As consumer preferences shift towards sustainable and visually appealing packaging, manufacturers are compelled to adopt lithographic printing techniques. This method offers high-quality prints and efficient production processes, which are essential for meeting market demands. In 2025, the packaging sector is projected to account for a substantial share of the lithographic printing chemicals, with an estimated growth rate of 4.5% annually. This trend indicates a robust market potential for lithographic printing chemicals, as companies seek to enhance their packaging aesthetics while adhering to sustainability standards.

Technological Innovations in Printing

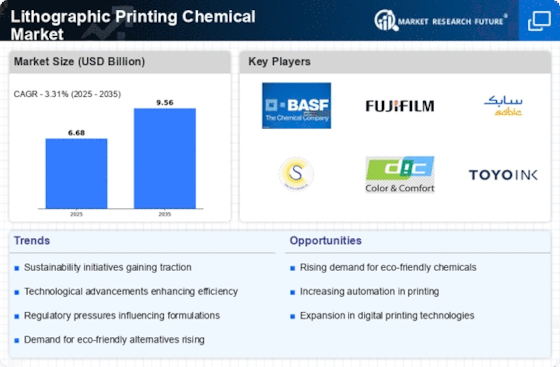

Technological advancements in printing processes are significantly influencing the Lithographic Printing Chemical Market. Innovations such as digital integration and automation are enhancing the efficiency and quality of lithographic printing. These technologies allow for faster production times and reduced waste, which are critical in a competitive market. The introduction of eco-friendly inks and chemicals is also noteworthy, as they align with the growing emphasis on sustainability. In 2025, it is anticipated that the adoption of these technologies will lead to a 6% increase in the demand for lithographic printing chemicals, as businesses strive to optimize their operations and meet consumer expectations.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are becoming increasingly stringent, impacting the Lithographic Printing Chemical Market. Manufacturers are required to adhere to various environmental regulations, which necessitate the use of safer and more sustainable chemicals in the printing process. This shift is driving innovation within the industry, as companies seek to develop compliant products that do not compromise on quality. In 2025, it is projected that the demand for eco-friendly lithographic printing chemicals will rise by approximately 7%, as businesses prioritize compliance and sustainability in their operations. This trend highlights the critical role of regulatory frameworks in shaping market dynamics.