Growth in Automotive Industry

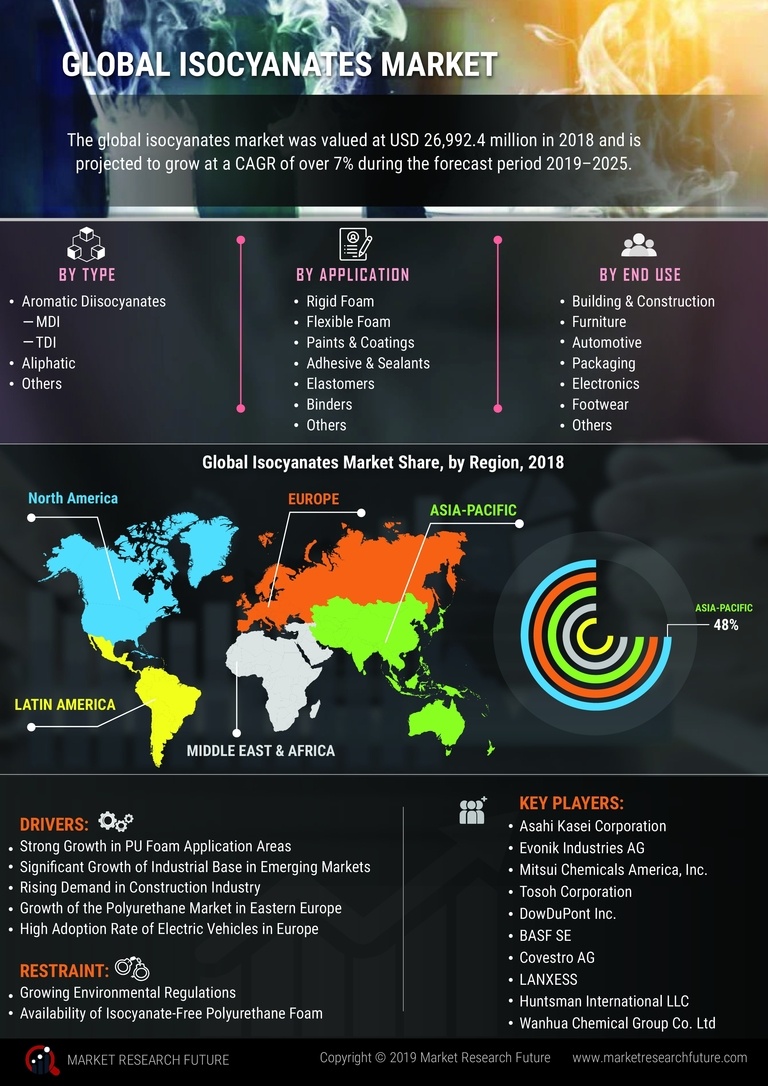

The automotive industry plays a crucial role in shaping the Isocyanates Market, as isocyanates are integral to the production of lightweight and high-performance materials. The shift towards electric vehicles and advanced composites is expected to enhance the demand for polyurethane materials, which utilize isocyanates. In 2023, the automotive sector represented around 25% of the total isocyanates market share, indicating a significant reliance on these chemicals for manufacturing components such as seats, dashboards, and insulation. As automotive manufacturers increasingly prioritize fuel efficiency and sustainability, the isocyanates market is poised for growth, driven by innovations in material science and engineering.

Increasing Regulatory Standards

The Isocyanates Market is increasingly shaped by regulatory standards aimed at ensuring safety and environmental protection. Governments and regulatory bodies are implementing stricter guidelines regarding the use and handling of isocyanates, which are known for their hazardous properties. In 2023, compliance with these regulations has become a critical factor for manufacturers, influencing their operational practices and product formulations. While these regulations may pose challenges, they also drive innovation as companies seek to develop safer alternatives and improve their processes. This regulatory landscape suggests that the isocyanates market will continue to evolve, with a focus on sustainability and safety, ultimately impacting market dynamics and growth opportunities.

Rising Demand in Construction Sector

The Isocyanates Market is experiencing a notable surge in demand, particularly driven by the construction sector. The increasing need for durable and high-performance materials in building applications is propelling the consumption of isocyanates, which are essential in the production of polyurethane foams and coatings. In 2023, the construction industry accounted for approximately 30% of the total isocyanates consumption, reflecting a robust growth trajectory. As urbanization continues to expand, the demand for insulation materials and protective coatings is likely to escalate, further bolstering the isocyanates market. This trend suggests that the construction sector will remain a pivotal driver for the isocyanates market, influencing production strategies and market dynamics in the coming years.

Expanding Applications in Consumer Goods

The Isocyanates Market is witnessing an expansion in applications across various consumer goods, including furniture, footwear, and textiles. The versatility of isocyanates in producing flexible and rigid foams is enhancing their adoption in these sectors. In 2023, consumer goods accounted for approximately 20% of the isocyanates market, reflecting a growing trend towards high-quality and durable products. As consumer preferences shift towards sustainable and innovative materials, manufacturers are increasingly incorporating isocyanates into their product lines. This trend indicates a potential for further market penetration and diversification, as companies seek to meet evolving consumer demands while leveraging the unique properties of isocyanates.

Technological Advancements in Production Processes

Technological advancements are significantly influencing the Isocyanates Market, particularly in production processes. Innovations in manufacturing techniques, such as the development of more efficient catalysts and processes, are enhancing the yield and quality of isocyanates. In recent years, the introduction of greener production methods has also gained traction, aligning with sustainability goals across industries. These advancements are expected to reduce production costs and improve the overall competitiveness of isocyanates in various applications. As companies invest in research and development, the isocyanates market is likely to benefit from enhanced efficiency and reduced environmental impact, positioning it favorably for future growth.