Regulatory Compliance

Stringent regulatory requirements across various industries are propelling the Global Industrial Weighing Machine Market Industry. Governments worldwide are enforcing regulations that mandate accurate weight measurements in sectors such as food and beverage, pharmaceuticals, and manufacturing. Compliance with these regulations not only ensures product quality but also enhances consumer safety. For instance, the food industry is subject to strict weight labeling laws, prompting manufacturers to invest in reliable weighing solutions. This regulatory landscape is expected to drive demand for advanced weighing machines, further contributing to the market's anticipated growth trajectory, reaching 653.7 USD Billion by 2035.

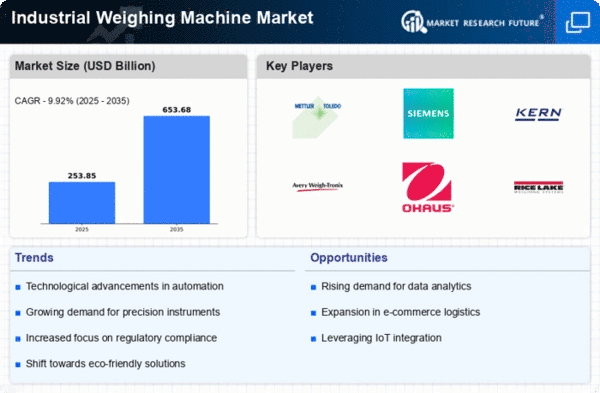

Market Growth Projections

The Global Industrial Weighing Machine Market Industry is poised for substantial growth, with projections indicating a rise from 230.9 USD Billion in 2024 to 653.7 USD Billion by 2035. This growth trajectory reflects a compound annual growth rate (CAGR) of 9.92% from 2025 to 2035. The increasing adoption of advanced weighing technologies across various sectors, coupled with the rising demand for precision and efficiency, underpins this optimistic outlook. As industries continue to evolve and seek innovative solutions, the market is likely to witness significant advancements, further solidifying its position as a critical component of global supply chains.

Sustainability Initiatives

Growing awareness of sustainability and environmental impact is influencing the Global Industrial Weighing Machine Market Industry. Companies are increasingly adopting eco-friendly practices, which often involve optimizing resource usage and minimizing waste. Accurate weighing systems play a crucial role in these initiatives by ensuring that materials are used efficiently and that waste is reduced. For instance, industries are implementing weighing solutions that facilitate recycling and waste management processes. This shift towards sustainability is expected to drive demand for innovative weighing technologies, contributing to the market's projected growth and aligning with global efforts to promote environmentally responsible practices.

Technological Advancements

The Global Industrial Weighing Machine Market Industry is experiencing rapid technological advancements that enhance precision and efficiency. Innovations such as digital load cells and automated weighing systems are becoming increasingly prevalent. These technologies not only improve accuracy but also reduce operational costs for businesses. For instance, the integration of IoT in weighing machines allows for real-time data monitoring and analytics, which can lead to better decision-making. As industries seek to optimize their processes, the demand for advanced weighing solutions is expected to rise, contributing to the market's projected growth from 230.9 USD Billion in 2024 to 653.7 USD Billion by 2035.

Rising Demand in E-commerce

The surge in e-commerce activities globally is significantly driving the Global Industrial Weighing Machine Market Industry. As online retail continues to expand, the need for efficient logistics and accurate weight measurement becomes paramount. Companies are increasingly investing in automated weighing solutions to streamline their operations and enhance customer satisfaction. For example, major logistics firms are adopting advanced weighing technologies to ensure compliance with shipping regulations and optimize freight costs. This trend is likely to contribute to the market's growth, with a projected CAGR of 9.92% from 2025 to 2035, reflecting the increasing reliance on precise weighing systems in the e-commerce sector.

Growth in Manufacturing Sector

The ongoing expansion of the manufacturing sector globally is a key driver for the Global Industrial Weighing Machine Market Industry. As production processes become more complex, the need for accurate and efficient weighing solutions is increasingly recognized. Industries such as automotive, chemicals, and consumer goods are investing in advanced weighing technologies to enhance productivity and quality control. For example, manufacturers are utilizing automated weighing systems to minimize human error and optimize material usage. This trend is likely to fuel the market's growth, with projections indicating a rise from 230.9 USD Billion in 2024 to 653.7 USD Billion by 2035, reflecting the sector's robust demand for precision weighing.